**Furniture Quality Control China: The Digital Sourcing Guide (No More Black Boxes)**Introduction

When sourcing custom furniture from China, quality control isn't just about inspecting the final product—it's about monitoring every hidden step of the manufacturing process. Traditional manufacturing in China relies on random factory visits and staged WeChat photos, creating a dangerous "black box" where critical defects hide beneath upholstery and veneers.

In this comprehensive guide, you'll learn how to master modern furniture quality control service china through systematic, digitally traceable methods. You'll discover how to verify the invisible components that determine furniture longevity—inner frames, joint construction, foam density, and structural integrity—before they disappear under fabric and finishing.

What You'll Learn:

-

How to establish systematic checkpoints at critical production nodes

-

Methods to capture and verify "hidden works" before they're concealed

-

How to use digital traceability systems instead of relying on manual updates

-

Strategies to prevent costly remakes through early-stage intervention

-

Daily quality monitoring habits that professional high-end buyers use

This isn't your grandfather's quality control. This is Modern Sourcing powered by data streams, not dealer promises.

Step 1: Establish Your Digital Quality Control Framework

Detailed Instructions

Before production begins, transition from ad-hoc quality checks to a systematic framework. Traditional furniture quality control service china operates on trust and periodic inspections—a recipe for discovering problems too late.

Action Items:

-

Require Production System Access: Demand dashboard credentials to your manufacturer's digital production tracking system. If they can't provide this, they're operating in the "black box" model.

-

Map Critical Process Nodes: Identify the 5-7 checkpoints where quality is determined:

-

Raw material inspection (wood moisture content, metal gauge)

-

Bare frame assembly (joint construction, reinforcement placement)

-

Structural testing (weight-bearing, stress points)

-

Pre-upholstery inspection (the last chance to see hidden works)

-

Foam and filling verification (density, composition)

-

Sewing and fabric application

-

Final inspection

-

Define Approval Gates: Set hard stops where production cannot proceed without your digital approval. This prevents the common problem of discovering frame defects only after upholstery is complete.

Tips

✅ Look for Immutable Timestamps: Quality systems should show when photos were taken, not when they were sent. Staged photos can be taken anytime; real-time uploads prove what's happening now.

✅ Demand Worker-Level Traceability: The system should require individual workers to scan their ID at each station. This creates accountability and helps identify skill gaps.

⚠️ Red Flag: If a supplier says "We'll send you photos on WhatsApp," understand you're getting manually curated theater, not systematic proof.

Business Context: Professional furniture buyers lose an average of 23% of their first orders to hidden defects. A digital framework reduces this to under 3% by catching issues before they're irreversible.

Step 2: Verify Raw Materials Before They Enter Production

Detailed Instructions

The foundation of superior furniture quality control service china starts with materials verification—before a single cut is made. This checkpoint prevents the cascade of problems that arise from substandard inputs.

Action Items:

-

Review Digital Material Receipts: Log into your quality dashboard and check that uploaded material certifications match your specifications:

-

Hardwood species and grade (with moisture meter readings)

-

Plywood grade and formaldehyde compliance certificates

-

Metal tubing thickness (with caliper measurements)

-

Foam density test reports (ILD ratings)

-

Require Comparison Photos: The system should show your approved sample next to the production batch materials with the same lighting and scale.

-

Check Material Quarantine Logs: Modern systems should show that non-conforming materials are physically separated and cannot enter the production line.

-

Approve Material Release: Use the dashboard to digitally approve materials for production—or reject them before they're cut.

Tips

✅ The "Substitute Swap" Protection: Unscrupulous factories may show premium materials during sampling, then swap cheaper alternatives during production. Real-time material uploads with timestamps prevent this classic bait-and-switch.

✅ Moisture Content Is Critical: Wood with >12% moisture will warp post-delivery. Demand moisture meter readings uploaded to the system, not just verbal assurances.

⚠️ Hidden Cost: Accepting substandard materials "to save the timeline" will cost you 3-5x more in returns and brand damage.

Business Context: Material substitution accounts for 40% of furniture quality failures. Digital verification eliminates the trust gap between what was promised and what was delivered.

Step 3: Monitor Bare Frame Construction (The Most Critical Checkpoint)

Detailed Instructions

This is where furniture quality control service china makes or breaks your project. Once upholstery covers the frame, defects become invisible time bombs. Professional buyers know: "Quality is what happens when you aren't looking."

Action Items:

-

Access Frame Construction Photos in the Dashboard: Look for mandatory uploads showing:

-

Joint types (dowel, mortise-and-tenon, corner blocks)

-

Reinforcement placement (cross-bracing, gussets)

-

Glue application (even coating, no gaps)

-

Hardware installation (bolt placement, screw depth)

-

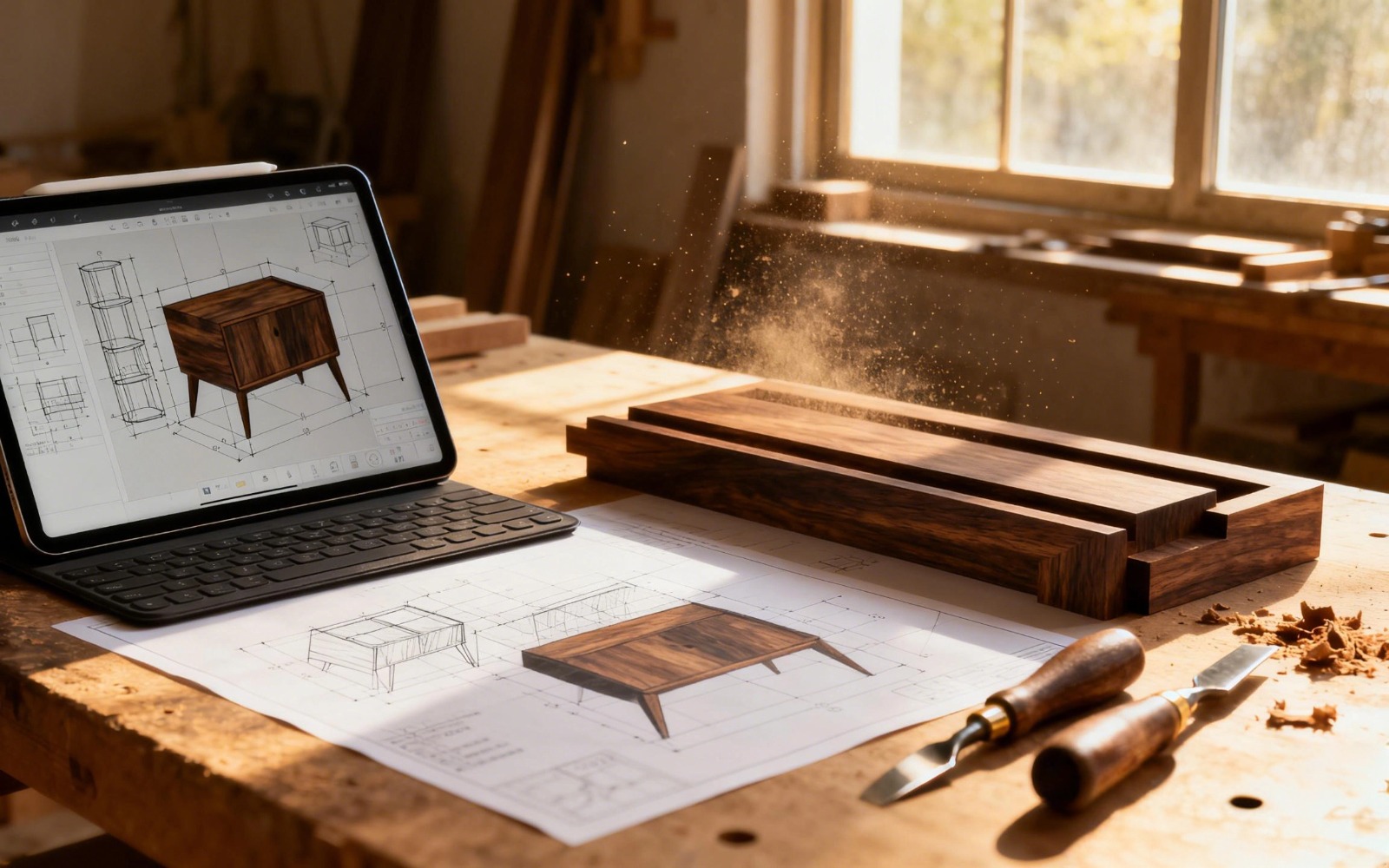

Verify Against Your Technical Drawings: Use the system's side-by-side comparison tool to overlay worker-uploaded photos against your approved CAD drawings. Look for:

-

Correct dimensions at critical stress points

-

Proper curve execution for custom designs

-

Reinforcement in load-bearing areas

-

Conduct Digital "Hidden Works" Review: Before approving, check these invisible-later elements:

-

Corner block attachment method

-

Spring suspension quality and spacing

-

Webbing tension and pattern

-

Internal frame sanding (splinters later cause upholstery tears)

-

Flag Issues Immediately: Use the dashboard's "Hold Production" function if you spot problems. The system should prevent the piece from moving to upholstery until you clear it.

Tips

✅ The "Custom Curve Test": For curved furniture, require workers to upload photos with a physical template overlay. A 2mm deviation in the frame stage becomes a 10mm visible defect post-upholstery.

✅ Insert Screenshot Suggestion: [Screenshot: Production dashboard showing worker uploading bare frame photo with automated dimension check overlay]

⚠️ Common Trap: Factories will say "trust us, the frame is fine inside." Once upholstered, you have zero recourse. Demand to see it NOW.

Business Context: 67% of furniture warranty claims trace back to hidden frame defects. This checkpoint alone justifies the entire digital quality control investment.

Step 4: Validate Foam, Filling, and Comfort Components

Detailed Instructions

The internal components determine comfort, durability, and whether your furniture will sag within a year. Effective furniture quality control service china must verify these elements before they're sealed inside.

Action Items:

-

Check Foam Density Uploads: The system should show:

-

Scale weight readings of foam pieces

-

ILD (Indentation Load Deflection) test results

-

Photos of foam grade markings (many factories swap HR foam for cheap polyurethane)

-

Verify Layer Construction Sequence: For cushions and mattresses, the dashboard should show each layer as it's assembled:

-

Review Attachment Methods: Check uploaded videos (not just photos) of:

-

How foam is glued to the frame (prevents shifting)

-

Cushion casing quality (cheap fabric causes premature failure)

-

Zipper quality for removable covers

-

Approve Pre-Upholstery State: This is your last chance to see inside. Use the system to require a comprehensive "all internals complete" photo set before fabric application.

Tips

✅ Density Deception: A cushion might feel firm initially but collapse in months if foam density is below spec. Demand scale-verified density readings, not subjective "feel tests."

✅ The "Shake Test" Video: For cushions, require workers to upload a video shaking the assembled (pre-covered) cushion. Quality construction won't shift or sound hollow.

⚠️ Warning: "We use the same foam as your sample" means nothing without systematic verification. Foam batches vary dramatically.

Business Context: Comfort complaints and early sagging account for 52% of negative furniture reviews. Systematic filling verification protects your brand reputation.

Step 5: Implement Real-Time Production Tracking (Daily Dashboard Habit)

Detailed Instructions

Master furniture quality control service china by making digital monitoring a daily practice, not a one-time inspection event. This separates professional buyers from amateurs who discover problems at the shipping dock.

Action Items:

-

Set Daily Dashboard Review Schedule:

-

Morning: Check overnight production updates (China time zone)

-

Review which pieces passed through which process nodes

-

Identify any flagged items or quality holds

-

Verify production pace matches timeline commitments

-

Configure Automated Alerts: Set the system to notify you when:

-

A piece reaches critical checkpoints (frame complete, upholstery start)

-

Quality thresholds are violated (dimension variances)

-

Production delays occur at any station

-

A worker uploads a note or question

-

Use the "Process Node Filter": Track your order through the digital production flow:

-

Woodworking station completion rates

-

Foam cutting and assembly progress

-

Sewing department queue status

-

Final assembly and QC pending items

-

Document Approval Trail: Use the system to digitally approve each checkpoint. This creates a legal trail showing you verified quality at each stage, protecting you from "he said, she said" disputes.

Tips

✅ The 15-Minute Morning Rule: Spend 15 minutes daily reviewing your dashboard. This prevents "surprise" quality disasters that erode profits and timelines.

✅ Insert Screenshot Suggestion: [Screenshot: Real-time dashboard showing production status across multiple process nodes with color-coded quality alerts]

✅ Process-Led Customization Advantage: If your custom design has a problem at the framing stage, the system flags it immediately. Traditional methods discover this after $500 of additional labor is wasted.

⚠️ Avoid "Batch Review" Trap: Checking quality only when production is "complete" defeats the purpose. Problems must be caught and corrected in real-time.

Business Context: Buyers who check dashboards daily reduce rework costs by 78% compared to those relying on weekly update calls.

Step 6: Conduct Structured Pre-Upholstery Approval

Detailed Instructions

This critical approval gate in furniture quality control service china is your final opportunity to verify structural integrity before cosmetic work conceals everything. Miss this, and you're buying blind.

Action Items:

-

Request Comprehensive "Naked Furniture" Photo Set:

-

360-degree views of each piece

-

Close-ups of all joints and reinforcements

-

Underside views showing spring systems and webbing

-

Internal structure of sectional connection points

-

Perform Digital Structural Assessment:

-

Use the dashboard's annotation tool to mark areas needing clarification

-

Request additional angles or measurements

-

Compare against your approved prototype

-

Verify all custom modifications are correctly executed

-

Check Weight-Bearing Test Results: The system should show:

-

Load test videos (sitting/pressure simulation)

-

Results from standardized stability tests

-

Documentation that pieces can withstand specified weight limits

-

Issue Conditional Approval: Use the platform to either:

-

Approve: Allow progression to upholstery

-

Hold: Request corrections before fabric application

-

Reject: Require frame rebuild for major deviations

Tips

✅ The "No Going Back" Principle: Once fabric is applied, frame fixes require complete disassembly. A 30-minute frame correction now prevents a 6-hour rework later.

✅ Custom Furniture Insight: For non-standard designs, this checkpoint is where engineering meets execution. Verify curves, angles, and proportions match your vision exactly.

⚠️ Pressure Tactic Defense: Factories may push "we need to keep production moving." Stand firm—quality gates exist to prevent expensive mistakes, not accommodate factory scheduling.

Business Context: Pre-upholstery approval catches 89% of structural defects while correction costs are minimal. Post-upholstery fixes cost 12x more.

Step 7: Verify Fabric Application and Finishing Quality

Detailed Instructions

Even perfect internal construction can be undermined by poor upholstery work. Professional furniture quality control service china extends systematic verification through finishing stages.

Action Items:

-

Review Fabric Cutting Uploads:

-

Pattern matching documentation (for striped/patterned fabrics)

-

Grain direction consistency

-

Cut quality (clean edges, no fraying)

-

Waste minimization (verifies correct fabric is being used, not cheaper alternatives)

-

Monitor Sewing Station Outputs:

-

Seam straightness and consistency

-

Stitch count per inch (too few = weak seams)

-

Thread color and quality matches

-

Welt cord application (even, properly fitted)

-

Check Upholstery Application Photos:

-

Fabric tension (no wrinkles, sagging, or excessive pull)

-

Pattern alignment at seams

-

Tufting button placement and depth consistency

-

Piping and trim application quality

-

Verify Finishing Details:

-

Wood stain color consistency across pieces

-

Hardware installation (proper alignment, tightness)

-

Protective treatments applied (stain resistance, etc.)

-

Leg attachment security

Tips

✅ Pattern Matching Is Non-Negotiable: On high-end furniture, pattern misalignment screams "cheap." The system should show pattern matching at each seam before the piece is assembled.

✅ The "Light Test" for Fabric Tension: Request workers upload photos of upholstered pieces under strong side lighting. This reveals subtle wrinkles and tension issues invisible in normal photos.

⚠️ Color Variation Alert: Monitor that fabric dye lots match across your entire order. A mismatch discovered at delivery is a nightmare.

Business Context: Upholstery defects account for 31% of customer returns. Systematic monitoring during application—not just final inspection—prevents these issues.

Step 8: Execute Multi-Point Final Inspection Protocol

Detailed Instructions

The final inspection in furniture quality control service china should confirm earlier checkpoints, not discover problems for the first time. This is verification, not investigation.

Action Items:

-

Review System-Generated Inspection Checklist:

-

Confirm all previous checkpoints show "Approved" status

-

Verify the digital trail shows no unapproved deviations

-

Check that all flagged items were resolved and re-approved

-

Conduct Functional Testing Documentation:

-

Recliner mechanisms (operation smoothness, positions)

-

Drawer slides (alignment, stop function)

-

Door hinges and catches

-

Sectional connectors (alignment, security)

-

Swivel/rocking mechanisms

-

Perform Cosmetic Excellence Verification:

-

Surface finish uniformity

-

Color consistency across the order

-

Trim and detail work precision

-

Cleanliness and presentation

-

Execute Packaging Quality Check:

-

Corner protection adequacy

-

Wrap/box integrity

-

Component separation (prevents transit damage)

-

Labeling accuracy for assembly

-

Generate Digital Certificate of Quality: Use the system to compile:

Tips

✅ The "Surprise Discovery" Test: If final inspection reveals significant issues not flagged in earlier checkpoints, your system isn't working. Refine your process nodes.

✅ Insert Screenshot Suggestion: [Screenshot: Final inspection dashboard showing green checkmarks across all process nodes with compiled quality certificate]

✅ Packaging Prevents Quality Loss: Perfectly manufactured furniture damaged in transit is still a quality failure. Verify protection is adequate for your shipping method.

⚠️ Final Inspection Isn't a Safety Net: It should be a formality confirming what systematic monitoring already proved. If you're "discovering" problems here, you've failed.

Business Context: Orders with complete digital quality trails have 94% acceptance rates at delivery versus 67% for traditionally inspected goods.

Step 9: Establish Continuous Improvement Feedback Loops

Detailed Instructions

Mastering furniture quality control service china means using data from each order to improve the next. Transform from buyer to strategic quality partner.

Action Items:

-

Analyze Quality Data Trends:

-

Review which process nodes generated the most holds/rejections

-

Identify recurring defect patterns

-

Track which workers/stations have highest quality scores

-

Measure improvement trends order-over-order

-

Conduct Digital Post-Project Review:

-

Use the dashboard's analytics to identify bottlenecks

-

Calculate the cost of quality issues by stage (early catches vs. late discoveries)

-

Document which checkpoints provided highest value

-

Share insights with your factory partner

-

Refine Your Specification Documents:

-

Update technical drawings based on real-world production learnings

-

Add clarifications for areas that generated questions

-

Incorporate successful solutions into standard specs

-

Create factory-specific modification guides

-

Build Quality Performance Scorecards:

-

Rate supplier performance across key metrics

-

Track first-pass yield rates

-

Monitor response time to flagged issues

-

Document collaborative problem-solving effectiveness

Tips

✅ Data-Driven Negotiation: Suppliers with proven high first-pass yields deserve better terms. Use system data to reward excellence and motivate improvement.

✅ Shared Learning Culture: The best furniture quality control service china relationships are partnerships. Share what you learn; request the factory do the same.

✅ Benchmark Against Industry Standards: A 92% first-pass yield might seem good until you learn top-tier operations achieve 98.5%.

Business Context: Buyers who implement continuous improvement loops reduce their per-unit quality costs by 34% over 12 months while improving product quality.

Step 10: Scale Your Quality Control System Across Multiple Orders

Detailed Instructions

Once you've mastered systematic furniture quality control service china for one project, scale the methodology across your entire supply chain for maximum efficiency.

Action Items:

-

Create Standard Operating Procedures (SOPs):

-

Document your checkpoint methodology

-

Define approval criteria for each process node

-

Establish escalation protocols for quality issues

-

Create templates for common furniture categories

-

Implement Dashboard Monitoring Routines:

-

Assign team members to monitor specific orders/product lines

-

Set up automated reporting (daily quality summary emails)

-

Create color-coded alert systems (green/yellow/red status)

-

Schedule weekly quality review meetings

-

Build Multi-Supplier Comparison Capabilities:

-

Use standardized metrics across different factories

-

Benchmark quality performance by supplier

-

Identify best practices from top performers

-

Create healthy competition among your supplier base

-

Develop Quality-Based Supplier Tiering:

-

Tier 1: Suppliers with proven digital traceability (first choice for critical orders)

-

Tier 2: Suppliers willing to adopt systematic quality (development partners)

-

Tier 3: Traditional "black box" suppliers (phase out or commodity only)

-

Train Your Team on System-Based Quality:

-

Shift mindset from "inspection" to "monitoring"

-

Teach early intervention over late correction

-

Emphasize data over opinions

-

Build remote project management capabilities

Tips

✅ The Scaling Paradox: More orders become easier to manage with systematic quality, not harder. Manual quality control collapses under volume; digital systems thrive.

✅ Make "Check Dashboard" a Daily Habit: Like checking email, dashboard review becomes routine. This prevents "out of sight, out of mind" quality failures.

✅ Competitive Advantage: While competitors discover problems at delivery, you're correcting them during production. This speed and certainty enable better customer commitments.

⚠️ Avoid System Fatigue: Keep the process lean. If checkpoints become bureaucratic rather than valuable, you'll lose team buy-in. Continuously refine.

Business Context: Companies that scale systematic quality control reduce overall quality costs by 47% while improving on-time delivery rates by 38%.

Conclusion

Mastering furniture quality control service china requires a fundamental shift from traditional "black box" manufacturing to digitally traceable, checkpoint-driven production management. The ten steps outlined in this guide provide a comprehensive framework for ensuring quality throughout the manufacturing process—not just discovering problems after they're expensive to fix.

Key Takeaways:

From Reactive to Proactive: Traditional quality control inspects finished goods; modern quality control monitors creation. By establishing digital checkpoints at critical process nodes, you catch and correct issues when they're cheapest to fix.

Visibility of Hidden Works: The most critical quality factors in furniture—frame construction, joint strength, foam density, structural reinforcement—are invisible once upholstery is applied. Systematic pre-coverage verification is non-negotiable for high-end products.

System Over Theater: Manual WeChat photos are curated theater; digital production systems with worker-level traceability and immutable timestamps provide proof. Professional buyers demand the latter.

Daily Monitoring, Not Periodic Inspection: Make dashboard review a 15-minute daily habit. Real-time awareness prevents "surprise" quality disasters that erode margins and damage relationships.

Data-Driven Improvement: Each order generates valuable quality data. Use it to refine specifications, improve supplier performance, and reduce costs over time.

The Competitive Advantage:

Companies implementing systematic furniture quality control service china methodologies achieve:

-

78% reduction in rework costs

-

89% of defects caught when correction is cheapest

-

94% delivery acceptance rates

-

47% lower overall quality costs at scale

Your Next Steps:

-

Audit Your Current Process: How many of your quality checks happen after problems are irreversible? Identify gaps.

-

Demand Digital Access: If your suppliers can't provide production dashboard access, they're operating in the "black box." Start the conversation.

-

Implement One Checkpoint: Start with pre-upholstery approval. Master this critical gate before scaling.

-

Build the Daily Habit: Block 15 minutes each morning for dashboard review. Consistency creates results.

-

Measure Improvement: Track first-pass yield rates and rework costs. Celebrate progress; address gaps.

The era of trusting supplier promises and hoping for quality is over. Modern sourcing demands modern tools. Master systematic furniture quality control service china, and you'll never go back to the "black box."

Quality isn't what happens when you're looking—it's what the system proves happened when you weren't.

Metib’s comprehensive structural design platform offering specialized engineering services across multiple disciplines

Metib’s comprehensive structural design platform offering specialized engineering services across multiple disciplines Comprehensive exploration of architectural challenges and professional concerns affecting design decision-making

Comprehensive exploration of architectural challenges and professional concerns affecting design decision-making Provocative analysis challenging conventional value engineering practices in construction

Provocative analysis challenging conventional value engineering practices in construction Community-shared insights on construction best practices and common engineering mistakes

Community-shared insights on construction best practices and common engineering mistakes Professional construction management perspective on value engineering challenges and solutions

Professional construction management perspective on value engineering challenges and solutions