Furniture Export Incoterms 2026: EXW vs FOB vs DDP (Cost & Risk Guide)

Introduction: Why Incoterms Matter More Than You Think in High-End Furniture Manufacturing

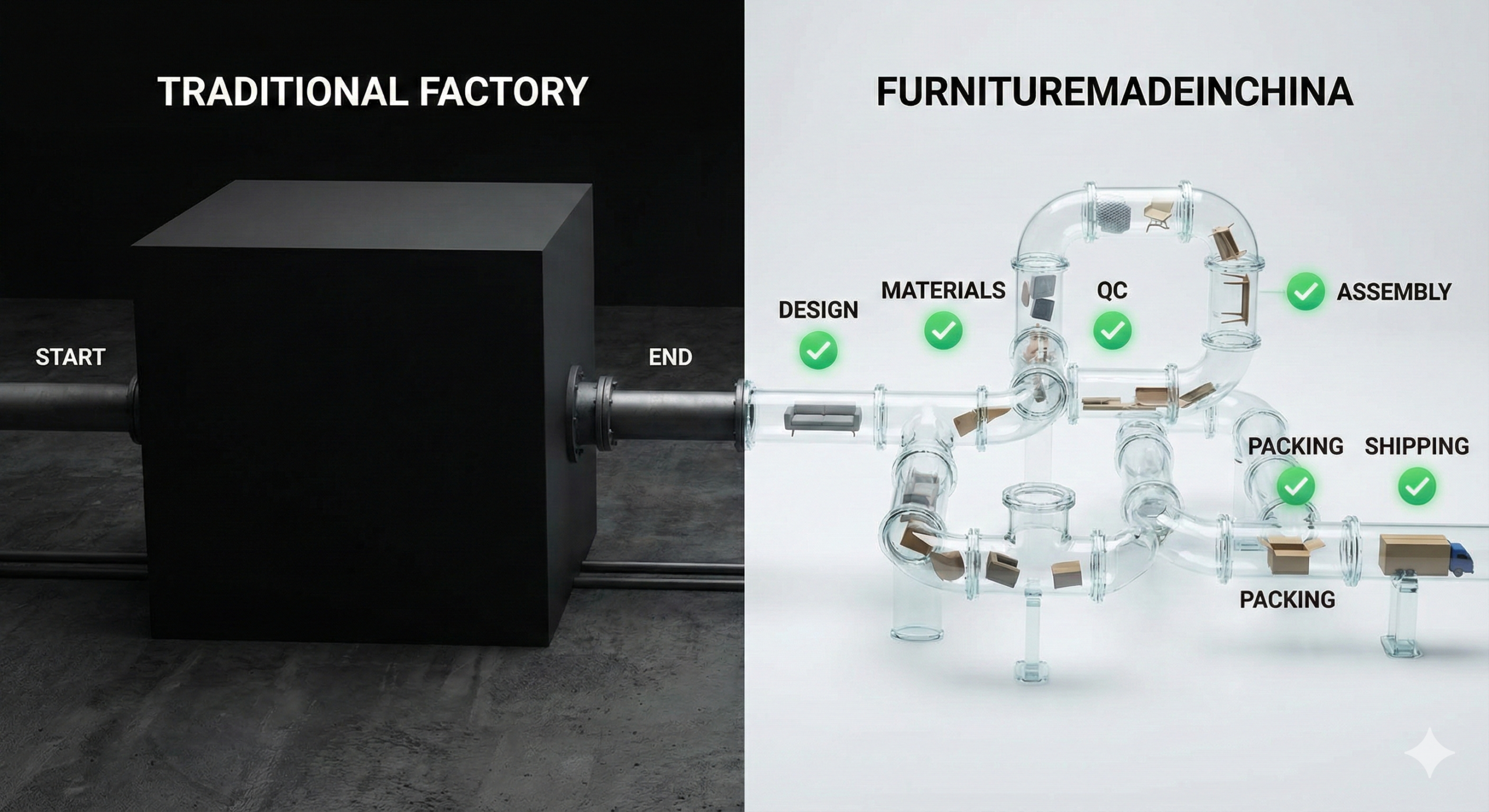

When sourcing premium custom furniture from China, most buyers obsess over aesthetics—the grain of Italian walnut, the stitching on Napa leather, the perfect curve of a sofa back. But here’s the uncomfortable truth: the wrong Incoterm can silently add 30% to your landed costs or leave you liable for damages during transit that occurred before you even took possession.

Understanding Incoterms 2026 for furniture export isn’t just bureaucratic paperwork—it’s the contractual DNA that determines who pays for what, who risks what, and who controls quality at which stage of your furniture’s journey from Chinese factory floor to your warehouse.

At FurnitureMadeInChina, we’ve observed a critical disconnect: Buyers invest heavily in digitally traceable manufacturing to ensure every foam density and joint strength is verified through our Digital Production System, yet they often sign Incoterms that hand over control the moment furniture leaves our facility—creating a “black box” during the most vulnerable phase: international logistics.

This comprehensive guide decodes the three most common Incoterms for furniture export—EXW (Ex Works), FOB (Free On Board), and DDP (Delivered Duty Paid)—and reveals how your choice directly impacts your ability to maintain the same transparency and quality assurance you demand during production.

What is Understanding Incoterms 2026 for Furniture Export (EXW vs FOB vs DDP)?

The Foundation: Incoterms Defined

Incoterms (International Commercial Terms) are standardized trade terms published by the International Chamber of Commerce (ICC) that define the responsibilities, costs, and risks between buyers and sellers in international transactions. The 2026 revision (building on the 2020 framework) introduces enhanced clarity around digital documentation and sustainability considerations—particularly relevant for furniture exports where provenance and compliance certificates matter.

For furniture exporters and importers, Incoterms answer three critical questions:

-

At what point does risk transfer from seller to buyer? (Damage, loss, delays)

-

Who arranges and pays for transportation, insurance, and customs?

-

What documentation must each party provide?

Why Furniture Export Requires Special Attention

Unlike electronics or textiles, furniture presents unique logistical challenges:

-

High volume-to-value ratio: A container of sofas might have lower unit value than smartphones but occupies vastly more space

-

Fragility of “hidden works”: Internal frame structures, foam layering, and joint integrity can be compromised during rough handling—defects invisible until end-use

-

Customization complexity: Bespoke pieces can’t be simply reordered if damaged; each item is unique

-

Multi-material composition: Wood, foam, fabric, and metal each have different handling requirements

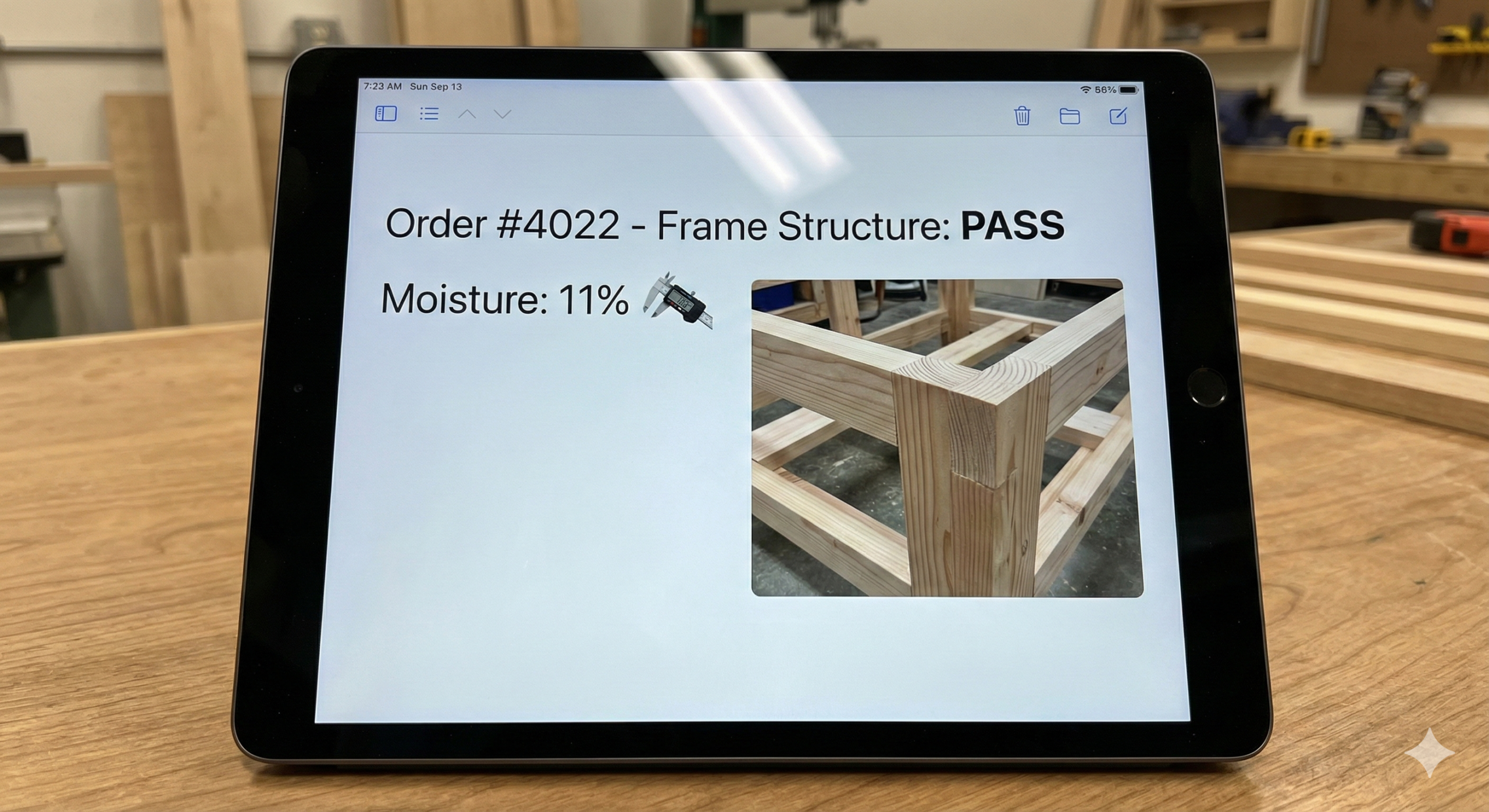

This is where digitally traceable manufacturing intersects with Incoterms strategy. Our system captures the pristine condition of your furniture’s hidden works before packaging—establishing a documented baseline. But your chosen Incoterm determines whether you retain control (and evidence) during the logistics phase.

EXW (Ex Works): Maximum Control, Maximum Responsibility

What is EXW?

Ex Works (EXW) represents the seller’s minimum obligation. Under EXW, the manufacturer makes the goods available at their factory premises (our facility in Guangdong, for example), and the buyer assumes all responsibilities and costs from that point forward.

Practical Example:

You order 50 custom dining chairs with intricate internal bracing (verified through our Digital Production System with scanned images of each mortise-and-tenon joint). Under EXW:

-

Our obligation ends when we notify you the chairs are ready for pickup at our warehouse

-

You arrange the truck to our factory, export customs clearance in China, ocean freight, import customs, and final delivery

-

Risk transfers the moment you (or your agent) collect the goods

When to Use EXW for Furniture Export

Ideal Scenarios:

-

You have established Chinese logistics partners: Experienced buyers with existing freight forwarders in China who can handle export procedures efficiently

-

You demand total supply chain control: When you want to select specific shipping routes, carriers, and insurance to maintain chain of custody

-

Consolidation needs: Combining furniture from multiple Chinese manufacturers into one container requires EXW from all suppliers

FurnitureMadeInChina Pro Tip:

Even under EXW, request loading supervision documentation from our team. Our workers can scan and photograph furniture placement in the container using the same Digital Production System—providing proof of proper loading before the “black box” of transit begins.

EXW Risks for Furniture Buyers

⚠️ The Export License Trap: China requires export licenses for certain hardwoods (like rosewood). Under EXW, you’re responsible for obtaining these, which can be practically impossible for foreign buyers without local presence.

⚠️ The VAT Refund Problem: Chinese factories typically quote EXW prices inclusive of VAT but expect you to handle the VAT export refund process—complex and time-consuming.

⚠️ Hidden Quality Breakpoint: There’s a dangerous gap between our Digital Production System’s final verification and when your logistics partner takes possession. Without proper handover protocols, damage accountability becomes murky.

FOB (Free On Board): The Balanced Middle Ground

What is FOB?

Free On Board (FOB) is the most common Incoterm for furniture exports from China. The seller delivers goods on board the vessel at the named port of shipment (typically Shanghai, Shenzhen, or Ningbo for furniture).

Cost and Risk Breakdown:

Seller’s Responsibilities (FurnitureMadeInChina):

-

Manufacturing (with full digital traceability)

-

Domestic transportation to Chinese port

-

Export customs clearance and documentation

-

Loading costs onto the vessel

Buyer’s Responsibilities:

-

Ocean freight from Chinese port

-

Marine insurance

-

Import customs clearance

-

Final inland delivery

Critical Point: Risk transfers when goods pass the ship’s rail at the port of loading.

The FOB Furniture Export Workflow

Let’s trace a real scenario—a high-end hotel in Dubai ordering 200 custom armchairs:

Phase 1: Production (Our Territory)

-

Our Digital Production System tracks each chair through Woodworking → Foam Station → Upholstery

-

Real-time dashboard shows moisture content of beech frames (must be <12% before advancing)

-

System flags Chair #47 where foam density scan shows 38kg/m³ instead of specified 45kg/m³

-

“The Case of the Wrong Foam” in Action: A worker accidentally grabbed the wrong foam roll. In a traditional “black box” factory, this would be discovered months later when the chair prematurely sags. Our system halted production at that station until the correct foam was scanned and verified.

Phase 2: Pre-Shipment (Still Our Territory)

-

Chairs packed in custom wooden crates with moisture barriers

-

Loading at factory documented via system scans

-

Truck transport to Shenzhen port (we arrange and pay)

-

Export declaration filed with commodity codes for “upholstered wooden seating”

Phase 3: Port Loading (Transition Point)

-

Container loaded onto vessel

-

Risk transfers here—any storm damage during ocean transit is now buyer’s concern

-

We provide Bill of Lading (B/L) as proof of shipment

Phase 4: Buyer’s Journey

-

Ocean freight to Jebel Ali port, Dubai

-

Import customs clearance

-

Final delivery to hotel site

When to Use FOB for Furniture Export

Ideal Scenarios:

-

Standard international purchases: You have reliable freight forwarders in your home country but not necessarily in China

-

Competitive freight shopping: You want to negotiate ocean freight rates independently

-

Insurance control: You prefer arranging marine insurance through your own underwriters who understand furniture value

Why FOB Complements Digital Traceability:

FOB allows us to extend our Digital Production System documentation through the domestic Chinese logistics phase. We can verify:

-

Furniture condition at factory (via production scans)

-

Furniture condition at port warehouse (via pre-loading inspection scans)

-

Proper container loading (via stevedore supervision)

This creates an unbroken digital chain of custody right up to the vessel, minimizing the “black box” gap.

FOB Pitfalls to Avoid

⚠️ The “Ship’s Rail” Ambiguity: Modern container shipping rarely involves goods literally crossing a ship’s rail. The 2026 Incoterms clarify this as “when goods are in the carrier’s custody at the port terminal.”

⚠️ Port Congestion Costs: If your nominated vessel is delayed, demurrage (container storage fees) at the Chinese port may fall on you under FOB.

⚠️ Communication Gaps: We’ve seen cases where buyers assume FOB includes inland delivery in China. Always confirm the specific FOB port in writing (“FOB Shenzhen,” not just “FOB”).

DDP (Delivered Duty Paid): Maximum Convenience, Maximum Cost

What is DDP?

Delivered Duty Paid (DDP) represents the seller’s maximum obligation. We deliver furniture to your specified address (your warehouse in New York, your showroom in London), fully cleared through customs, with all duties and taxes paid.

Complete Seller Responsibility:

-

All manufacturing and quality control

-

Export procedures in China

-

International freight and insurance

-

Import customs clearance in your country

-

Payment of all import duties and VAT

-

Final delivery to your specified location

Risk transfers only when goods are ready for unloading at the named destination.

The DDP Furniture Export Journey

Scenario: A boutique furniture retailer in Stockholm orders 10 custom sofas with complex curved backs requiring precise internal framing.

Our End-to-End Responsibility:

-

Production Phase:

-

Digital Production System tracks the critical curved frame stations

-

Each curve radius verified against CAD specifications via digital templates

-

Foam contouring scanned at multiple nodes to ensure compound curves match design

-

System uploads 847 verification points per sofa before upholstery covers the “hidden works”

-

-

Chinese Domestic Logistics:

-

Professional packing for long-haul transit

-

Trucking to Shanghai port

-

Export customs handled by our licensed broker

-

-

International Transit:

-

Ocean freight Shanghai → Gothenburg

-

Marine insurance (typically 110% of invoice value)

-

We assume all risk during transit

-

-

Swedish Import:

-

Customs clearance at Gothenburg

-

Payment of Swedish import duties (~3.2% for furniture) and VAT (25%)

-

Trucking to retailer’s Stockholm address

-

Unloading assistance

-

Your Only Obligation: Be ready to receive the sofas at your location.

When to Use DDP for Furniture Export

Ideal Scenarios:

-

First-time importers: No experience with international logistics or customs procedures

-

Small orders: The administrative overhead of arranging freight isn’t justified for 5 chairs

-

Predictable budgeting: You want one all-inclusive price with no surprise customs bills

-

Complex compliance markets: Countries with intricate import regulations (EU’s CE marking, California’s Prop 65)

The High-End Custom Furniture Argument for DDP:

When you’re ordering €50,000 worth of bespoke pieces with intricate internal structures, the last thing you want is to scramble for a customs broker while your container racks up port storage fees. DDP lets you focus on what our Digital Production System does best—ensuring quality during manufacturing—while we handle the “commodity phase” of getting completed goods to you.

DDP Challenges in Furniture Export

⚠️ Price Opacity: DDP quotes can be difficult to compare. Are duties calculated at current rates or estimated? Does it include unloading, or just curbside delivery?

⚠️ VAT Recovery Issues: If you’re VAT-registered in the EU, you might prefer to pay VAT yourself and reclaim it, rather than having us pay it (where it becomes an unrecoverable cost).

⚠️ Country Expertise Limitations: We’re experts in Chinese export regulations and major markets (US, EU, Australia). For secondary markets (Argentina, South Africa), our DDP capabilities may be limited.

⚠️ The Final Mile Risk: Under DDP, we’re responsible until delivery to your address. But if your receiving dock can’t accommodate a 40-foot container truck, additional trans-loading costs emerge.

FurnitureMadeInChina’s DDP Transparency Protocol:

Unlike “black box” pricing, our DDP quotes break down:

-

Manufacturing cost (verified through Digital Production System data)

-

Chinese domestic logistics (actual contracted rates)

-

Ocean freight (current market rates with carrier specified)

-

Insurance (policy terms provided)

-

Destination customs and duties (tariff codes and calculation methodology shown)

-

Final delivery (route and carrier specified)

This maintains the same transparency philosophy as our production tracking—no hidden steps, no black boxes.

FF&E Procurement Strategy: How to Choose the Right Incoterm

Decision Framework: Four Critical Questions

1. What’s Your Logistics Expertise Level?

| Experience Level | Recommended Incoterm | Rationale |

| :— | :— | :— |

| First-time importer | DDP | Minimize risk and complexity |

| Some experience, trusted freight forwarder | FOB | Balance cost and control |

| Experienced with Chinese logistics | EXW or FOB | Maximum cost optimization |

| Consolidating multiple suppliers | EXW from all | Unified logistics management |

2. How Critical is Quality Control Through Logistics?

For high-end custom furniture where “hidden works” matter:

Best Practice Approach:

-

Use FOB as the Incoterm

-

Extend our Digital Production System documentation through port loading

-

Arrange your own freight forwarder with furniture handling expertise

-

Require periodic container condition reporting during transit

-

Conduct receiving inspection using our production scan baseline as reference

This creates an unbroken digital trust chain:

-

Production verification (our system)

-

Loading verification (our supervised documentation)

-

Transit monitoring (your freight partner)

-

Receiving inspection (compared against our baseline data)

Avoid the “Double Black Box”: Using EXW with an unknown freight forwarder creates two opaque phases—Chinese domestic transit AND international shipping—with no quality accountability.

3. What’s Your Volume and Frequency?

Order ProfileIncoterm StrategyLarge recurring orders (quarterly containers)FOB + negotiate annual freight ratesSmall trial order (5 pieces)DDP to minimize setup complexityMedium order with multi-factory sourcingEXW from all + consolidation warehouseOne-time large project (hotel furnishing)DDP with fixed price guarantee

4. What are the Import Compliance Complexities?

Use DDP when:

-

Destination country has complex furniture regulations (flammability standards, formaldehyde limits)

-

You’re importing restricted materials (certain hardwoods under CITES)

-

Tariff classification is ambiguous (is it a “chair” or “furniture part”?)

Use FOB when:

-

You have specialized customs brokers for tariff engineering (optimizing HS codes)

-

Your company has AEO (Authorized Economic Operator) status for expedited customs

-

You need specific customs documentation for tax incentives or trade agreements

The Business Benefits of Understanding Incoterms 2026 for Furniture Export

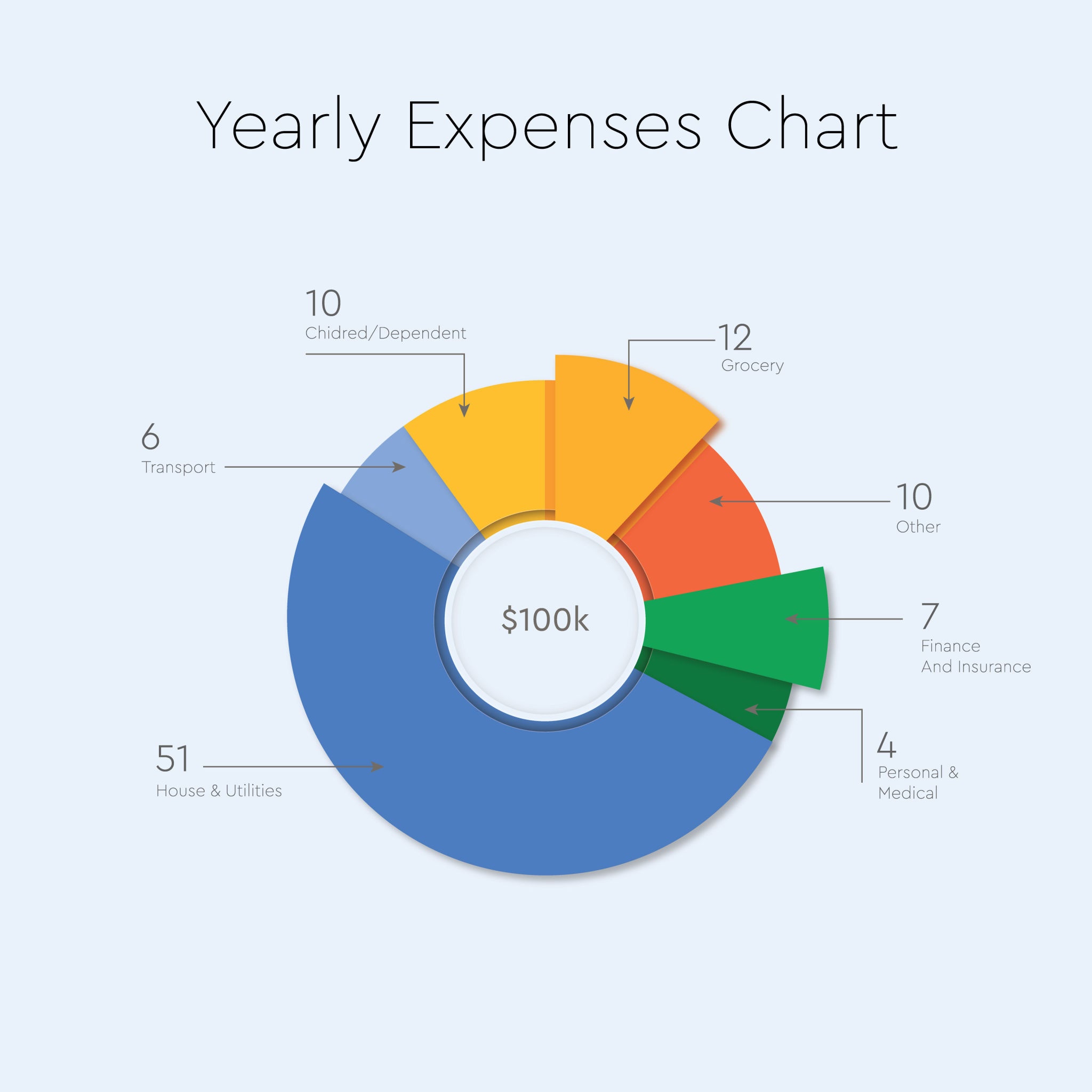

1. Controlling FF&E Costs & Budgets

Real Example:

Real Example: A US hospitality buyer received two quotes for identical dining sets:

Supplier A: $12,000 DDP New York

Supplier B (FurnitureMadeInChina): $8,500 FOB Shenzhen

Surface analysis suggests Supplier A is more expensive. But when the buyer added Freight ($1,200), Insurance ($150), and Customs Broker fees ($180) to Supplier B’s quote, the total was $10,030. By choosing FOB, the buyer saved nearly $2,000 on the FF&E budget—money that could be reinvested into higher quality fabrics or better wood finishes.

-

Freight ($1,200)

-

Insurance ($150)

-

US customs duty at 0% (under USMCA for qualifying wood)

-

Customs broker fee ($180)

-

Inland delivery ($270)

Total: $10,300

Supplier B was actually cheaper, and the buyer gained control over carrier selection and insurance coverage.

The Digital Traceability Advantage: Our system’s detailed material composition data (wood species, foam origin, fabric content) allowed the buyer’s customs broker to accurately classify goods and even claim duty exemptions—impossible with traditional “black box” factories that provide vague material descriptions.

2. Risk Management and Liability Clarity

“The Case of the Crushed Credenza”:

A luxury retailer ordered an ornate credenza with intricate marquetry work (every veneer piece scanned during assembly via our Digital Production System).

-

Scenario A (EXW): Credenza arrives damaged. Manufacturer claims it left factory perfect (our digital scans prove this). Freight forwarder claims it arrived damaged at Chinese port. Buyer’s insurance denies claim, saying export packing was inadequate (seller’s responsibility under EXW). Result: Finger-pointing, no compensation.

-

Scenario B (FOB): Damage occurs during ocean transit. Clear liability: buyer’s marine insurance covers it. Our digital pre-shipment scans prove factory condition. Claim settled in 3 weeks.

-

Scenario C (DDP): Damage discovered at delivery. Entirely our responsibility and insurance. Buyer suffers zero financial loss (though delivery is delayed).

Incoterm choice = risk allocation clarity.

3. Cash Flow and Working Capital Management

Different Incoterms have different payment trigger points:

IncotermTypical Payment TriggerCash Flow ImpactEXWGoods ready at factory (earliest)Buyer pays before goods even leave ChinaFOBBill of Lading issuedBuyer pays when goods on vesselDDPDelivery at destination (latest)Buyer pays only upon receipt

For high-end custom furniture with 8-12 week production cycles, Incoterm choice affects when your capital is tied up:

-

EXW: You might pay when goods are ready but won’t receive them for another 6-8 weeks (ocean transit + customs)

-

DDP: You pay only when goods arrive, keeping capital available longer

The Digital Production System Financial Benefit: Our real-time production dashboard lets buyers see exactly when payment triggers will occur (not guesswork), enabling better treasury planning.

4. Competitive Advantage in Your Market

Story: Two Retailers, Two Strategies:

Retailer X (traditional sourcing):

-

Uses DDP from “black box” factory

-

Receives goods 14 weeks after order

-

Discovers inferior foam density after 6 months of customer use

-

No documentary proof of specification breach

-

Cannot enforce warranty claims

Retailer Y (modern sourcing with FurnitureMadeInChina):

-

Uses FOB with Digital Production System access

-

Monitors production in real-time via dashboard

-

Catches foam density issue at Day 12 of production (before upholstery)

-

Issue corrected immediately; no delay

-

Receives goods Week 14 with complete digital dossier

-

Can market furniture with “digitally verified quality documentation”

Result: Retailer Y has lower defect rates, faster time-to-market correction, and can command premium pricing for “traceable quality.”

Why Understanding Incoterms 2026 for Furniture Export is Important: The Quality Assurance Connection

The Critical Insight Most Buyers Miss

Here’s what separates sophisticated buyers from novices: Incoterms aren’t just about logistics—they’re about extending quality control through the supply chain.

Traditional thinking:

-

Production = Quality control phase

-

Logistics = Administrative phase

Modern thinking (especially for high-end custom furniture):

-

Production = Controlled quality phase (our Digital Production System)

-

Logistics = Uncontrolled risk phase (potential damage, substitution, environmental exposure)

-

Incoterm choice = How far you extend quality visibility

The “Hidden Works” Lifecycle

For a premium sofa with complex internal structure:

Stage 1: Manufacturing (Visible Through Digital Production System)

-

Frame joinery scanned and verified

-

Foam density tested and logged

-

Spring tension measured at each coil

-

Status: Fully documented, immutable records

Stage 2: Packaging

-

Wrapped, crated, containerized

-

Risk: Hidden works now literally hidden inside packaging

-

Mitigation: Pre-packaging final scans create baseline

Stage 3: Logistics (THE BLACK BOX ZONE)

-

Domestic transit in China

-

Port handling

-

Ocean voyage

-

Destination port handling

-

Domestic transit in destination country

Environmental hazards:

-

Moisture (container condensation can cause wood swelling)

-

Temperature extremes (affect glue bonds)

-

Physical shocks (can crack internal joints)

-

Delays (wood-boring insects in long port storage)

Critical Question: At what point during Stage 3 do you gain visibility and control?

-

EXW: From Chinese factory gate (earliest, but requires Chinese logistics expertise)

-

FOB: From vessel loading (balanced approach)

-

DDP: Only at your destination warehouse (latest, but zero logistics burden)

The Modern Quality Assurance Strategy

Best Practice for High-End Furniture:

-

Production Phase: Use a manufacturer with Digital Production System (that’s us) to create irrefutable baseline documentation

-

Incoterm Selection: Choose FOB to gain control at the port, while seller handles complex Chinese export procedures

-

Logistics Extension: Work with freight partners who:

-

Understand furniture handling (not just commodity container shipping)

-

Provide container atmosphere monitoring (humidity/temperature sensors)

-

Conduct mid-transit inspections if voyage exceeds 30 days

-

Document receiving condition with photographic evidence

-

-

Receiving Verification: Compare delivered condition against Digital Production System baseline scans

This creates a “glass supply chain” that extends our “glass factory” philosophy—no black boxes from raw material to your warehouse.

When Should You Use Understanding Incoterms 2026 for Furniture Export: Practical Scenarios

Scenario 1: Launching a New Furniture Line (Startup/Small Business)

Situation: You’re a designer launching a collection of 15 chair designs, ordering 10 pieces of each (150 chairs total) for initial inventory.

Recommended Approach:

-

Incoterm: DDP to your warehouse

-

Rationale: Minimize complexity while you focus on market launch; single vendor relationship

-

Digital Production System Benefit: Use our real-time production dashboard to create marketing content (“watch your chairs being made”) while we handle all logistics

Alternative: If budget is extremely tight, use FOB + freight forwarder recommended by us (we can introduce partners with furniture expertise)

Scenario 2: Established Retailer Expanding Product Range

Situation: You operate 8 showrooms, have existing freight relationships, ordering quarterly containers of mixed furniture.

Recommended Approach:

-

Incoterm: FOB to your preferred destination port

-

Rationale: Leverage your existing freight negotiated rates; maintain logistics control

-

Digital Production System Benefit: Provide your freight forwarder with our pre-shipment scan data to verify condition at Chinese port loading vs. destination receipt

Payment Terms: Negotiate Letter of Credit (LC) at sight against Bill of Lading to align payment with FOB risk transfer

Scenario 3: Large Hospitality Project (Hotel/Restaurant Chain)

Situation: Furnishing a 300-room hotel—need 300 headboards, 150 sofas, 75 dining tables, all custom-designed with strict completion deadline.

Recommended Approach:

-

Incoterm: DDP to project site with liquidated damages clause for late delivery

-

Rationale: You need guaranteed delivery; can’t afford logistics uncertainties on critical path

-

Digital Production System Benefit: Real-time production monitoring allows your project manager to see exact completion status and proactively adjust installation schedules

Contract Additions:

-

Require phased delivery (furnishing guest rooms floor-by-floor as construction completes)

-

Penalty clauses for delays beyond our control trigger only after proven documentation (our system provides this)

Scenario 4: Interior Designer Ordering Client-Specific Pieces

Situation: You’re specifying furniture for individual high-net-worth clients; each order is unique (one sofa, two chairs, etc.).

Recommended Approach:

-

Incoterm: DDP to your receiving warehouse

-

Rationale: Administrative burden of arranging freight for single-piece shipments is prohibitive

-

Digital Production System Benefit: Provide clients with access to production dashboard—they can watch “their” sofa being made, viewing the exact foam density verification, frame joinery scans, etc. (major value-add for luxury clients)

Price Justification: The premium you pay for DDP is offset by the client experience value and zero logistics risk

Scenario 5: Furniture Wholesaler/Distributor

Situation: You import containers of furniture monthly, distribute to retailers across your region.

Recommended Approach:

-

Incoterm: EXW + consolidation warehouse in China

-

Rationale: Volume justifies establishing Chinese logistics infrastructure; maximum cost control

-

Digital Production System Benefit: Our system can integrate with your Chinese consolidation warehouse—verify goods condition when transferred from our factory to warehouse, creating accountability chain

Advanced Strategy: Negotiate annual FOB rates based on guaranteed volume, but maintain EXW option for urgent small orders that you can expedite through your Chinese partners

Incoterms 2026 Updates Relevant to Furniture Export

Key Changes from 2020 to 2026

While the official Incoterms 2026 release will finalize specific language, the International Chamber of Commerce has signaled these focus areas:

1. Digital Documentation Standards

Impact on Furniture Export:

-

Electronic Bills of Lading (eBL) now standard practice under all maritime Incoterms (FOB, CFR, CIF)

-

Digital certificates of origin, phytosanitary certificates (for wood products), and compliance documentation accepted

-

FurnitureMadeInChina Integration: Our Digital Production System can now auto-generate export documentation packages that comply with 2026 digital standards—reducing document preparation time from days to minutes

2. Sustainability and Carbon Accounting

New Expectation:

-

Sellers may need to provide carbon footprint data for transportation under DDP terms

-

Documentation of sustainable sourcing (FSC-certified wood, recycled foam) becoming standard export documentation

Our Advantage: Our system already tracks material origins at granular level—we can generate carbon reports showing:

-

Wood source forest and transportation emissions

-

Manufacturing energy consumption per piece

-

Packaging material carbon footprint

3. Enhanced Insurance Clarity

Furniture-Specific Relevance:

-

Clearer definitions of “adequate insurance” for high-value custom goods

-

Under DDP, explicit requirement to disclose insurance coverage levels

Best Practice: For furniture over $10,000 per piece, specify “All Risks” coverage at 110% invoice value, including coverage for “inherent vice” (internal defects manifesting during transit)

4. Security and Compliance Costs

New Allocation Rules:

-

Clearer responsibility for security screening costs (X-ray, physical inspection)

-

Export control compliance (especially for rare wood species under CITES)

Under FOB: Seller (us) handles export security compliance

Under EXW: Buyer responsible—can be complex for foreign parties

Common Mistakes to Avoid When Selecting Incoterms for Furniture Export

Mistake 1: Choosing EXW Without Chinese Presence

The Problem: You saw EXW pricing was $2,000 lower than FOB and thought you’d save money.

The Reality:

-

You can’t legally handle export customs as a foreign entity without Chinese representative

-

Your freight forwarder charges $1,500 “export service fee” to do what we would’ve done under FOB

-

VAT refund process requires Chinese tax registration (impossible for you)

-

You end up paying $2,800 more than FOB, with added complexity

Lesson: EXW only makes sense if you have established Chinese logistics infrastructure or are consolidating multiple suppliers.

Mistake 2: Assuming DDP Means “Zero Hassle”

The Problem: You ordered DDP thinking you’d have zero involvement.

The Reality:

-

Customs requires additional documentation (business license, importer number)

-

Your country’s furniture safety regulations require YOUR company name on compliance labels (we can’t do this remotely)

-

Delivery truck arrives but your loading dock has height restrictions—trans-loading needed at your expense

Lesson: DDP means we handle the process, but you still need to provide destination-country-specific information and ensure receiving capability.

Mistake 3: Mixing Incoterms with Payment Terms Inappropriately

The Problem: You negotiated FOB but agreed to “payment before shipment.”

The Risk:

-

Under FOB, risk transfers when goods are on vessel

-

If you pay before shipment, you’ve paid for goods before you have risk responsibility

-

If goods are damaged at port before loading, you’ve paid but don’t yet own them (seller still has risk)

Best Practice Alignment:

IncotermRecommended Payment TriggerEXW70% deposit, 30% before collectionFOBLetter of Credit at sight against Bill of LadingDDP30-day payment terms after delivery confirmation

This aligns payment with risk transfer.

Mistake 4: Ignoring the “Named Place” Specification

The Problem: Your purchase order just said “FOB” without specifying port.

The Disaster:

-

We shipped FOB Ningbo (closest to our factory)

-

Your freight forwarder had contracts at Shanghai port (400km away)

-

Transloading cost: $1,200

-

Delay: 8 days

Lesson: Always specify the complete Incoterm:

-

✅ “FOB Shenzhen”

-

✅ “DDP 123 Warehouse Street, Los Angeles, CA 90021”

-

❌ “FOB China” (ambiguous)

-

❌ “DDP USA” (which city? which address?)

Mistake 5: Forgetting That Incoterms Don’t Cover Ownership Transfer

Critical Misunderstanding:

Incoterms define cost and risk transfer, but NOT ownership transfer. That’s governed by your sales contract.

Example Confusion:

Under FOB, goods are on the vessel (risk has transferred to you). But the Bill of Lading is consigned to us until you pay. You have the risk, but we still have ownership.

Solution: Your sales contract should explicitly state: “Ownership transfers upon full payment” (or whatever you negotiate). This works in conjunction with, but separately from, Incoterms.

Integrating Digital Traceability with Incoterm Strategy: The FurnitureMadeInChina Advantage

The Traditional Sourcing Black Box Problem

Conventional Furniture Export Flow:

-

Production: You maybe get some WeChat photos if the salesman remembers

-

Quality Inspection: Third-party inspector visits for 2 hours, checks visible surfaces

-

Shipment: Goods disappear into logistics black box

-

Receipt: You discover issues 8 weeks later

-

Dispute: “He said, she said”—no systematic proof

Accountability Gap: Even if you have a clear Incoterm defining who’s responsible, you can’t prove when damage occurred.

The Modern Traceable Sourcing Approach

Our Integrated System + Incoterm Strategy:

Phase 1: Production (Digital Glass Factory)

-

Every production station requires worker scan to unlock next step

-

Frame construction: 24+ verification points logged with timestamps

-

Foam installation: Density meter readings uploaded automatically (no manual input = no fudging data)

-

Upholstery: Photos captured before fabric covers critical “hidden works”

System Rule: A worker literally cannot move a sofa from Frame Station to Foam Station until the system confirms all frame scans are complete and within spec.

Human vs. System:

“A salesman can forget to photograph the internal corner blocks. A QC inspector might skip them if they’re in a hurry. Our system won’t let the piece advance to the next production node until corner block images are uploaded with timestamp and station ID.”

Phase 2: Pre-Shipment Documentation

-

System auto-generates complete digital dossier per piece:

-

Material traceability (wood origin, foam supplier, fabric lot)

-

200+ verification scans per item

-

Comparison against approved CAD design (deviation alerts)

-

Packaging verification (correct desiccants, moisture barriers)

-

Baseline Establishment: This becomes your “as-manufactured” reference point.

Phase 3: Incoterm Transition Points

Factory to Port (Our Responsibility):

-

GPS Tracked Trucking: We manage the domestic transport from our facility to the Shenzhen/Ningbo terminal.

-

Port Arrival Verification: Upon arrival at the port warehouse, our team (or designated agent) performs a “Gate-In Scan.” This proves the goods survived the domestic trucking phase intact.

-

Loading Supervision: We document the container loading process with photos, verifying correct stacking, moisture barrier installation, and desiccant placement.

-

The Handover: Once the container is loaded on the vessel, we upload the Bill of Lading and the Final Quality Dossier to your client dashboard.

Ocean Transit & Arrival (Your Visibility):

-

Risk Transfer: As the ship leaves the port, the risk technically transfers to you (and your marine insurance).

-

The “Evidence” Advantage: If the goods arrive damaged at your warehouse, you simply scan the QR code on the item.

-

Scenario: A chair leg is broken.

-

Action: You compare the damaged chair to our “Port Arrival Scan” and “Loading Photos.”

-

Result: You have irrefutable proof that the damage occurred during the voyage (insurance covers it), not at the factory (which insurance often disputes).

-

Conclusion: Don’t Let Logistics Be the Weak Link

In the world of high-end custom furniture, you aren’t just buying wood and fabric; you are buying a result—a pristine installation that delights your clients.

While DDP offers convenience for beginners, and EXW offers control for logistics experts, FOB combined with Digital Traceability represents the “Sweet Spot” for most B2B buyers. It balances cost control with risk management.

But regardless of which Incoterm you choose (2026 or otherwise), the golden rule remains: Never accept a black box.

Ready to secure your supply chain? Use our Furniture Logistics Calculator to compare EXW vs. FOB costs for your next project, or contact our team to see a demo of how our Digital Production System protects your investment from factory floor to hotel lobby.

Frequently Asked Questions about Furniture Export Incoterms

Q: Which Incoterm is best for importing furniture from China? A: For most B2B buyers, FOB (Free On Board) is the best balance. It gives you control over ocean freight costs and insurance while the supplier handles complex Chinese export procedures.

Q: Does DDP include unloading at my warehouse? A: Typically, No. DDP (Delivered Duty Paid) usually covers delivery to your door (curbside), but you are responsible for unloading the furniture from the container unless specifically negotiated otherwise.

Q: Who pays for damages under FOB? A: Once the furniture is loaded onto the vessel at the Chinese port, the risk transfers to the buyer. Any damage during ocean transit should be covered by your marine insurance policy.