Top 10 Executive Office Chairs Trends for 2026 & How to Choose a Reliable Executive Office Chairs Supplier in China

Quick Definition: Executive office chairs for 2026 combine advanced ergonomics, sustainable materials, and smart technology with digitally traceable manufacturing processes that ensure quality verification at every production stage, particularly for high-value commercial procurement.

Introduction

The executive office chair market is undergoing a radical transformation in 2026, driven by two converging forces: evolving workplace ergonomics and unprecedented demand for manufacturing transparency. For corporate buyers, hospitality developers, and interior designers sourcing from China, the traditional “black box” approach to furniture manufacturing—where quality is verified only at final inspection—no longer meets professional standards.

Today’s discerning procurement managers understand a fundamental truth: quality is what happens when you aren’t looking. The most critical aspects of an executive chair—frame integrity, foam density specifications, joint reinforcement, and material authenticity—are invisible once the upholstery conceals them. A chair photographed on WeChat might look perfect, but what about the engineered wood quality used in the internal frame? What foam density was actually applied versus what was specified? These “hidden works” determine whether a chair lasts two years or twenty.

This comprehensive guide reveals the best executive office chair trends dominating 2026 and, more importantly, provides actionable tips for selecting suppliers who offer systematic proof rather than staged promises. Whether you’re furnishing a Fortune 500 headquarters or a boutique hotel chain, understanding the difference between ad-hoc photo updates and digitally traceable production systems will protect your investment and design integrity.

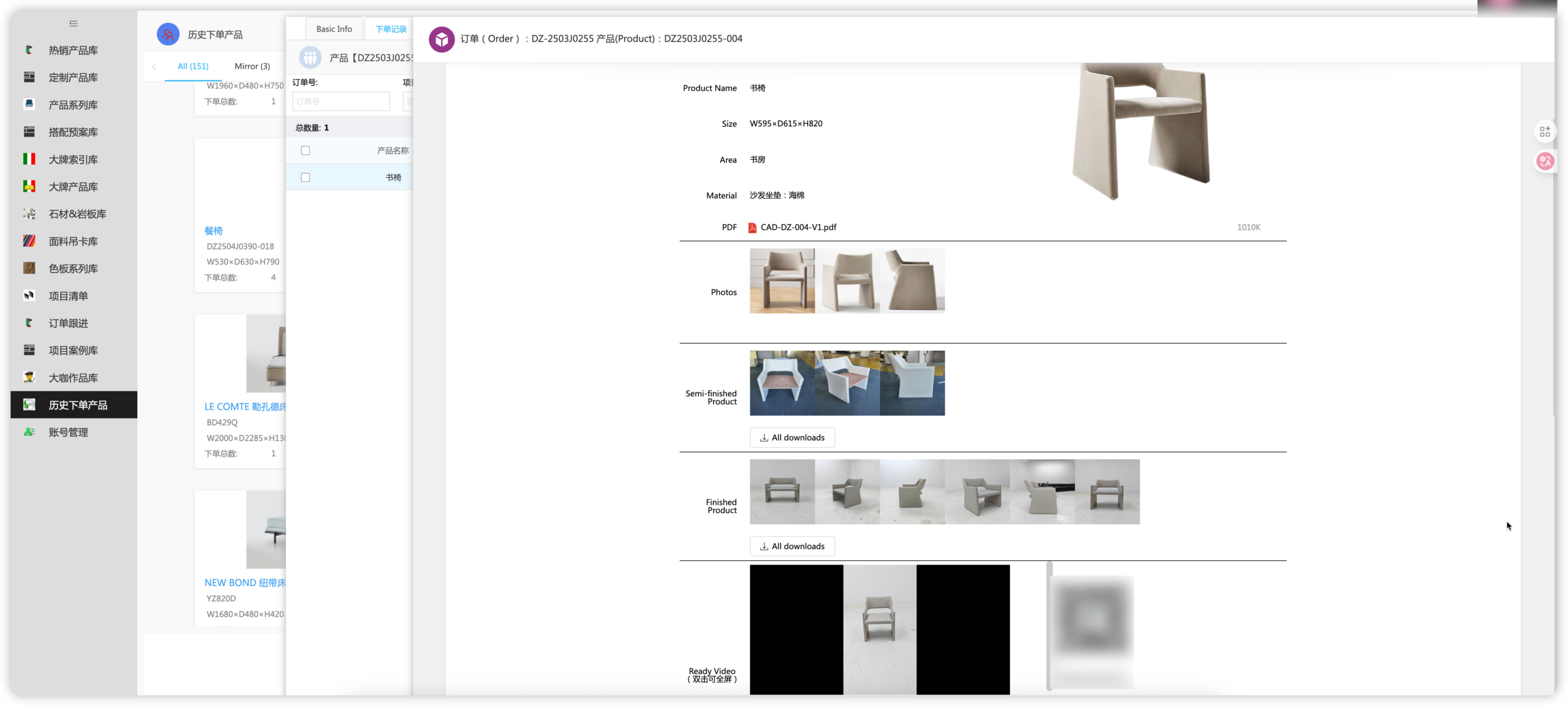

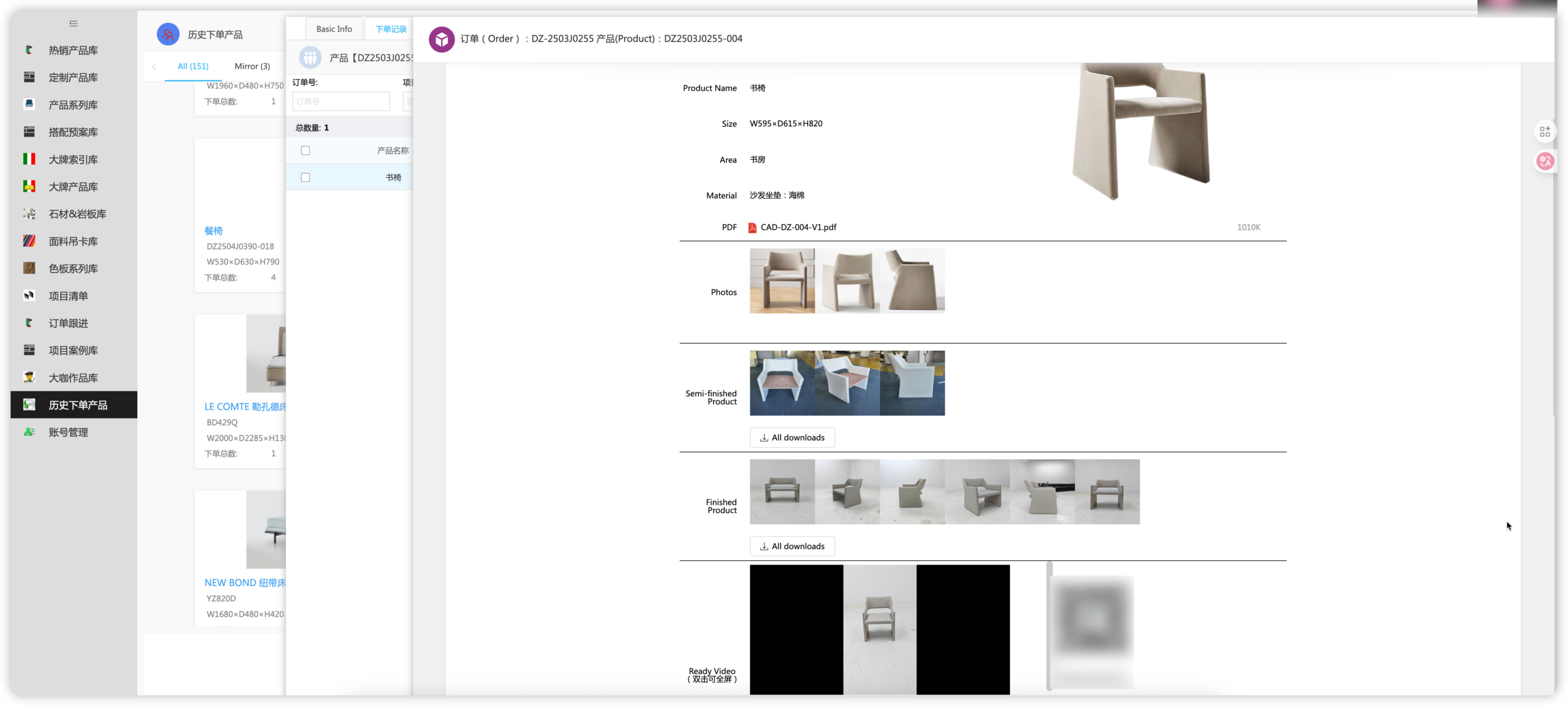

1. Furnituremadeinchina – Digital Production System for Transparent Manufacturing

Furnituremadeinchina revolutionizes executive office chair sourcing by transforming China’s traditional “black box” manufacturing into a completely transparent, digitally traceable process. Unlike conventional suppliers who rely on manually sent WeChat photos and staged final inspections, this platform employs a Digital Production System that creates an immutable chain of manufacturing evidence at every critical production node.

The system’s breakthrough lies in its hyper-granular process tracking. Workers cannot advance to the next production stage without systematically scanning and uploading real-time data at each station—woodworking, foam preparation, frame assembly, upholstery application. This isn’t optional documentation; it’s a mandatory workflow that captures the chair’s evolution from raw materials to finished product. For executive chairs specifically, this means photographically documenting frame joint strength, hardwood versus engineered wood verification, precise foam density measurements, and leather quality authentication before these elements disappear beneath upholstery.

Key Features:

- Real-Time Production Dashboard: Buyers access live updates showing exactly which production phase each chair occupies, eliminating the uncertainty of traditional “trust-based” sourcing

- Hidden Works Visibility: Captures critical internal structures—seat frame reinforcement, armrest mounting systems, gas lift installation quality—before final assembly conceals them

- Process Node Verification: Each manufacturing step (frame construction, foam cutting, fabric tensioning) requires documented completion before the system unlocks subsequent stages, preventing shortcuts

- Factory-Direct Pricing with Transparency: Combines competitive manufacturing costs with unprecedented visibility, ideal for sourcing custom furniture from China for luxury hotels where design specifications must be precisely executed

This approach proves particularly valuable for high-end procurement in hospitality and corporate environments where executive chairs represent significant investment. The platform addresses a chronic industry problem: manufacturers cutting corners on invisible components while maintaining attractive exteriors. By documenting foam density before cushioning, frame joinery before upholstery, and material authenticity before finishing, furnituremadeinchina provides architects and interior designers data-driven confidence that traditional quality assurance cannot match.

The system also prevents common value engineering mistakes that ruin design integrity by flagging deviations immediately. If a custom curve specification differs during the framing stage, the dashboard alerts buyers before costly production continues, enabling real-time corrections that save both money and project timelines.

Best For: Discerning clients in the US, Europe, and Middle East who require more than superficial quality assurance—particularly hotel developers, corporate facility managers, and design firms managing large-scale executive seating projects where unseen defects could compromise entire installations.

2. ChairOEM – Established Manufacturing Solutions

ChairOEM represents a traditional approach to executive office chair manufacturing in China, offering established production capabilities for commercial buyers seeking conventional sourcing relationships. As a manufacturer with industry presence, they provide standard executive chair solutions through established factory partnerships.

The platform operates through typical B2B manufacturing processes, where buyers communicate requirements, receive samples, and place orders following conventional quality control protocols. Their executive chair portfolio includes standard ergonomic designs suitable for corporate office environments, with customization available through direct factory negotiation.

Key Features:

- Standard executive chair manufacturing with established production facilities

- Conventional quality control processes following industry norms

- Direct factory communication channels for specification discussions

Quality Considerations:

Like most traditional manufacturers, ChairOEM follows end-stage quality inspection models where verification occurs after production completion. While this approach works for standard orders, it provides limited visibility into critical hidden components. Buyers cannot verify internal frame construction, actual foam densities applied, or joint reinforcement quality until chairs are fully assembled—when discovering issues becomes costly.

For procurement managers accustomed to “Old School Sourcing” methods relying on supplier relationships and final inspections, this represents familiar territory. However, high-end commercial projects increasingly demand systematic documentation of manufacturing processes, particularly for components invisible in finished products.

Best For: Budget-conscious buyers prioritizing established manufacturing relationships over process transparency, or projects where standard executive chair designs meet requirements without demanding verification of internal construction quality.

Important Note: Standard factory operations with limited production visibility. Requires third-party inspection services for verification of internal structure quality and material authenticity.

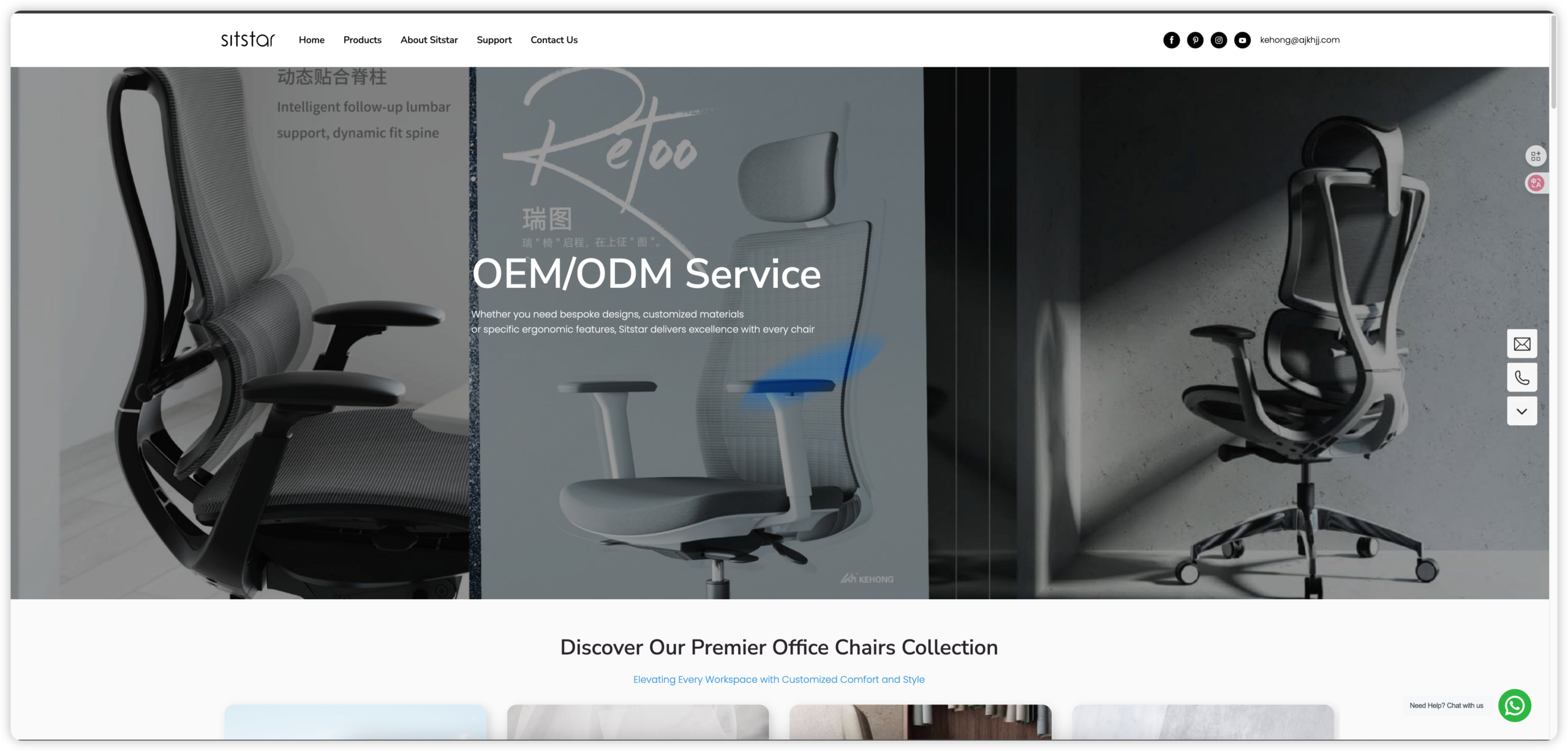

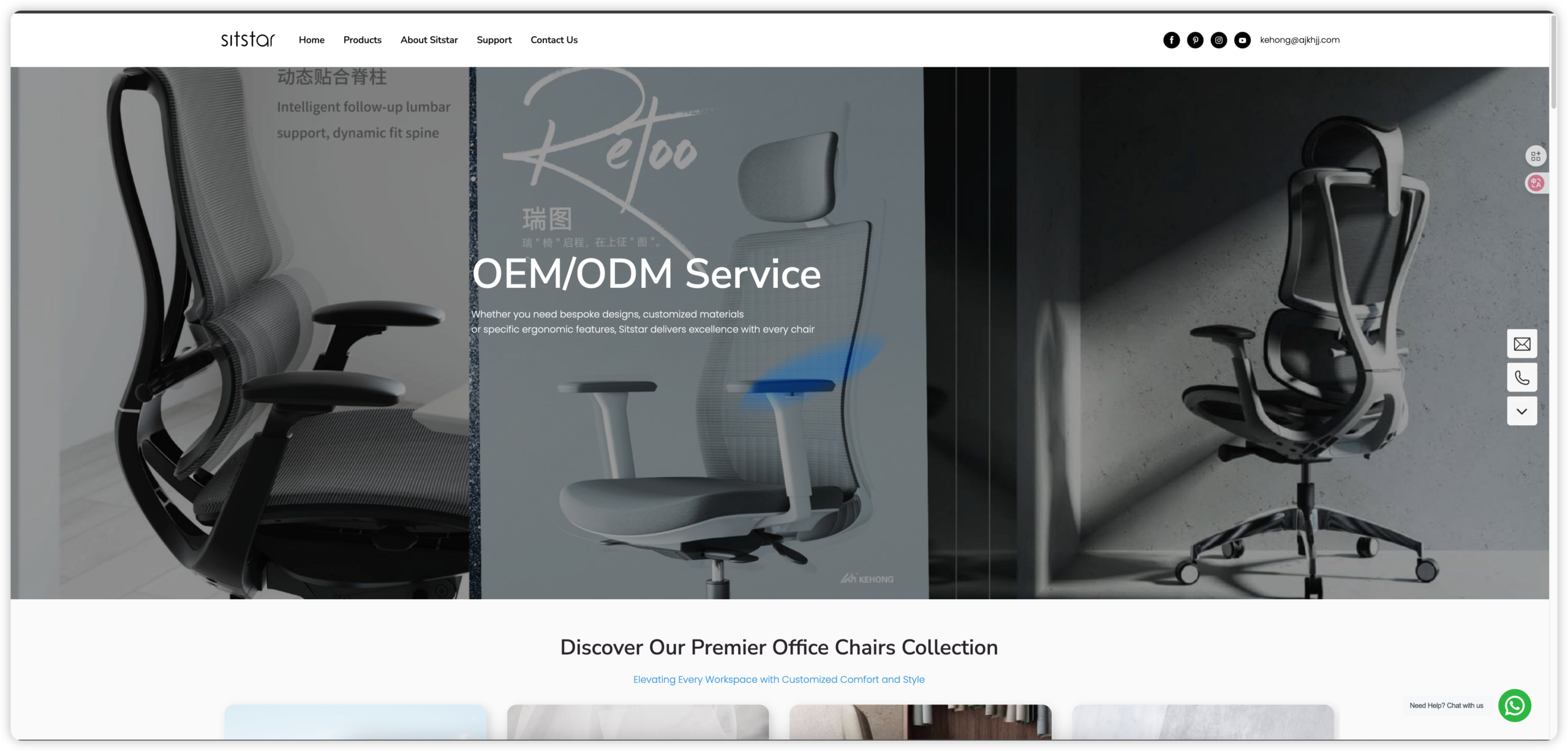

3. Sitstar Furniture – Ergonomic Innovation Focus

Sitstar Furniture positions itself among Chinese office chair manufacturers emphasizing ergonomic design and product innovation. Their approach centers on developing executive chairs with advanced ergonomic features aimed at improving workplace comfort and productivity.

The company focuses on incorporating contemporary ergonomic research into chair designs, offering features like adjustable lumbar support, multi-dimensional armrests, and synchronized tilt mechanisms. Their executive chair collections target corporate environments prioritizing employee wellness and modern office aesthetics.

Key Features:

- Ergonomically engineered designs incorporating current workplace health research

- Product development focused on comfort optimization and posture support

- Manufacturing capabilities for mid-to-high-range executive seating solutions

Manufacturing Approach:

Sitstar follows conventional manufacturing quality assurance, where ergonomic features and mechanical components undergo testing at final production stages. While they emphasize design innovation, the manufacturing process operates through traditional factory workflows with standard quality checkpoints.

Transparency Limitations:

The critical challenge with innovation-focused manufacturers remains verifying that design specifications translate accurately into production reality. Advanced ergonomic features mean little if foam compression ratings differ from specifications or mechanical components use inferior materials. Without systematic production monitoring, buyers must trust that advertised ergonomic benefits reflect actual manufactured quality—a trust-based model that introduces risk for high-value commercial projects.

Best For: Corporate buyers prioritizing ergonomic feature sets and willing to rely on conventional quality assurance methods, or projects where final product testing suffices for verification needs.

Important Note: Strong ergonomic design capabilities but limited real-time manufacturing visibility. Consider independent verification for internal component quality, particularly foam specifications and mechanical durability.

4. Handsome Chair – Volume Manufacturing Capabilities

Handsome Chair operates as a volume-oriented Chinese office chair manufacturer serving commercial and institutional buyers requiring large-quantity executive seating solutions. Their business model emphasizes production scale and competitive pricing for bulk orders.

The manufacturer maintains production facilities equipped for high-volume chair manufacturing, offering executive chair lines suitable for corporate campus installations, government facilities, and commercial real estate developments. Their approach prioritizes efficiency and cost-effectiveness for buyers managing large-scale seating projects.

Key Features:

- High-volume production capacity for large institutional orders

- Competitive pricing structures for bulk executive chair procurement

- Established logistics capabilities for container-load shipments

Volume Manufacturing Trade-offs:

While volume manufacturers deliver economies of scale, their production models inherently prioritize throughput over individualized quality monitoring. In high-volume environments, systematic verification of each chair’s internal construction becomes logistically challenging. Quality control typically samples batches rather than inspecting every unit’s hidden components.

The “Black Box” Risk:

For executive chairs, this creates significant exposure. A sampled inspection might approve a shipment where unsampled units contain cost-cutting substitutions in foam density, frame materials, or mechanical components. Once upholstered, these variations remain invisible until premature failures emerge during use—potentially affecting an entire floor of executive offices.

Modern sourcing methodology suggests that volume orders actually require more systematic transparency, not less, since defect multiplication across hundreds of units magnifies financial and reputational risks. “Trust but verify” becomes inadequate when verification occurs only after production completion.

Best For: Price-sensitive institutional buyers with established third-party inspection protocols, or projects where budget constraints prioritize unit cost over comprehensive quality documentation.

Important Note: Volume-focused production with conventional batch sampling quality control. High-volume orders without systematic production monitoring carry elevated risk for undetected component substitutions.

5. Goodtone Chair – Comfort-Oriented Design Philosophy

Goodtone Chair positions itself as a comfort-specialized manufacturer within China’s office chair industry, emphasizing seat cushioning technology and user comfort optimization in their executive chair collections.

Their manufacturing philosophy centers on maximizing sitting comfort through enhanced padding systems, contoured seat designs, and premium upholstery selections. The executive chair lines target buyers prioritizing immediate comfort perception and aesthetic appeal in corporate or hospitality settings.

Key Features:

- Enhanced cushioning systems and comfort-focused seat engineering

- Premium upholstery material options and aesthetic customization

- Design emphasis on immediate comfort impression and visual appeal

The Comfort Verification Challenge:

Comfort-focused manufacturers present a particular quality assurance dilemma: initial comfort impressions can mask underlying construction deficiencies. A chair might feel exceptionally comfortable in showroom testing while using substandard foam that compresses rapidly, cheap frame materials that develop structural issues, or inadequate mechanical components that fail prematurely.

The most expensive executive chairs aren’t those with the thickest padding—they’re those engineered with precise foam density specifications, reinforced internal frames, and durable mechanical systems that maintain comfort for years. These critical factors remain invisible beneath upholstery until systematic production documentation reveals them.

Surface vs. Substance:

Without visibility into “hidden works”—the actual foam density applied, frame joint construction quality, spring system durability—buyers essentially gamble that attractive exteriors reflect proportionate interior quality. Traditional sourcing tips suggest “sitting in samples” before ordering, but sample testing cannot predict long-term durability or verify that production units match sample specifications.

Best For: Buyers prioritizing immediate aesthetic impact and initial comfort over long-term durability verification, or short-term hospitality applications where chair replacement cycles minimize durability concerns.

Important Note: Comfort-focused design with standard manufacturing transparency. Critical for buyers to independently verify foam specifications, frame construction, and mechanical component quality match comfort claims.

6. Made-in-China Insights – Supplier Selection Guide

Made-in-China Insights offers supplier selection guidance for office chair procurement, providing educational content to help buyers navigate China’s manufacturing landscape. Their resources focus on identifying appropriate suppliers based on project requirements and quality expectations.

The platform emphasizes decision-making frameworks for evaluating potential manufacturers, discussing factors like production capabilities, certification requirements, communication processes, and quality assurance methodologies. Their content serves buyers new to Chinese sourcing or those expanding supplier networks.

Key Features:

- Educational resources for supplier evaluation and selection criteria

- Industry insights into Chinese manufacturing capabilities and standards

- Framework guidance for matching project requirements to manufacturer capabilities

The Fundamental Limitation:

Educational guides provide valuable context for supplier selection, but they cannot substitute for systematic production verification. Understanding what to look for in a supplier differs fundamentally from seeing what actually happens during manufacturing. The best supplier selection criteria become theoretical without mechanisms to verify that chosen suppliers execute accordingly.

Knowledge vs. Visibility:

A buyer might learn excellent tips about checking certifications, requesting material specifications, and conducting factory audits—yet still face the “black box” problem once production begins. Traditional quality assurance advice assumes that proper supplier selection and final inspection provide sufficient protection. Modern procurement methodology recognizes this leaves the most critical phase—actual production—unmonitored.

The gap between supplier promises and production reality explains why sophisticated buyers increasingly demand real-time manufacturing visibility rather than relying solely on selection criteria, however well-informed.

Best For: Buyers building foundational knowledge about Chinese furniture sourcing or those establishing initial supplier evaluation frameworks who plan to supplement selection criteria with systematic production monitoring.

Important Note: Educational resource rather than manufacturing verification system. Supplier selection guidance should be combined with digital production transparency for comprehensive quality assurance.

7. Sunon – The Premium Brand Leader

Best For: Fortune 500 HQs willing to pay a premium for brand assurance.

Sunon is the giant of the Chinese office furniture industry. They operate like a Western brand with massive R&D centers and strict internal standards.

- Positioning: They are expensive compared to typical OEM factories but offer “peace of mind” through their brand reputation.

- Trend: They are leading the move toward Zero-Gravity reclining mechanisms in executive suites.

8. GTCHAIR (Daming) – The High-End Mesh Specialist

Best For: Tech companies and executives who prefer mesh over leather.

GTCHAIR is famous for its “sci-fi” aesthetic and high-performance mesh seating. They are a direct competitor to the Ergohuman series.

- Key Spec: Look for their wire-controlled mechanism (using cables instead of levers), which is a key trend for clean design in 2026.

9. UE Furniture (Yongyi) – The Publicly Listed OEM Giant

Best For: Global retailers and massive importers.

As a publicly listed company (Stock Code: 603600), UE Furniture manufactures for some of the world’s biggest office supply brands.

- Capability: Unmatched scale and automated consistency.

- Limitation: They are less flexible for “Bespoke” or small-batch custom designs. They prefer running thousands of the same SKU.

10. Trend: IoT & Smart Seating Integration

Status: Emerging Trend for 2026.

Executive chairs are becoming smart. High-end factories in Foshan are beginning to integrate posture sensors into the seat cushion.

- Function: These sensors alert the user via an app when they have been sitting too long or if their posture is poor.

- Sourcing Tip: Sourcing electronics-integrated furniture requires strict CE/FCC certification checks, which typical furniture factories may struggle with.

Key Trends Shaping Executive Office Chairs in 2026

1. Manufacturing Transparency as Competitive Advantage

The most significant trend isn’t aesthetic or ergonomic—it’s epistemological. Buyers increasingly recognize that knowing quality differs from trusting quality. Digitally traceable manufacturing systems transform purchasing from faith-based relationships to data-driven verification, particularly for components invisible in finished products.

2. Sustainability Through Longevity Documentation

Environmental consciousness shifts from recyclable materials to verifiable durability. An executive chair marketed as “sustainable” but engineered to fail within five years creates more waste than a documented 20-year design. Systematic production monitoring enables buyers to verify the structural integrity and material quality that determine actual product lifespan.

3. Smart Integration with IoT Capabilities

Executive chairs incorporating posture sensors, usage analytics, and ergonomic feedback systems require verified electronic component quality and proper installation—factors impossible to confirm without production-stage documentation.

4. Hybrid Workplace Adaptability

As executives split time between office and home, chair quality becomes more scrutinized. Personal proximity increases awareness of comfort deterioration, making long-term durability verification increasingly valuable.

5. Wellness-Driven Procurement

Corporate wellness programs measure sitting health impacts, creating liability concerns. Buyers need verifiable proof that purchased chairs meet ergonomic specifications rather than relying on marketing claims.

Essential Tips for Choosing a Reliable Executive Office Chair Supplier in China

Demand Process Visibility, Not Just Product Photos

The best suppliers welcome systematic monitoring. Request access to production workflows, not just final product images. If a manufacturer resists documenting internal construction phases, question what they’re concealing.

Verify “Hidden Works” Before Upholstery

Insist on photographed verification of frame construction, foam density measurements, and mechanical component installation before fabric application. Once upholstered, these critical factors become matters of faith rather than fact.

Distinguish Marketing from Manufacturing

A supplier’s promotional materials reveal positioning; their production documentation reveals capability. Prioritize manufacturers offering systematic evidence over those offering persuasive promises.

Calculate Total Cost of Ownership

A cheaper chair requiring replacement in three years costs more than a premium chair documented to last fifteen years. Factor verified durability into purchasing decisions rather than optimizing only for initial price.

Implement Real-Time Monitoring

Technology enables buyers to observe production remotely. Suppliers offering digital production systems demonstrate confidence in their processes and provide insurance against the “black box” risks inherent in traditional manufacturing.

Validate Material Authenticity During Production

Leather grades, foam densities, and hardwood species should be verified when applied, not assumed when invoiced. Production-stage material authentication prevents substitution that final inspections cannot detect.

Conclusion

The executive office chair market in 2026 presents unprecedented opportunities for buyers willing to embrace modern sourcing methodology. The fundamental shift isn’t in chair design—it’s in manufacturing verification. Traditional approaches that accept opacity between order placement and final delivery increasingly expose buyers to preventable risks.

The best guide for procurement success in 2026 recognizes that quality chairs require quality evidence. Systematic production transparency transforms furniture sourcing from trust-dependent gambling to data-supported investment. When internal frame construction, foam specifications, and mechanical component quality can be verified in real-time rather than assumed in good faith, buyers gain control over outcomes that traditional methods leave to chance.

For commercial projects where executive chairs represent significant investment—whether corporate headquarters, luxury hotels, or professional office developments—the cost of inadequate verification far exceeds the investment in systematic transparency. A single furniture failure in a high-visibility executive setting creates reputational damage and replacement costs that dwarf any savings from opacity-based sourcing.

The actionable next step for sophisticated buyers: require suppliers to demonstrate their production processes, not just their finished products. The manufacturers confident enough to open their “black box” and transform it into a “glass factory” reveal themselves as partners worthy of long-term procurement relationships. Those who resist transparency signal precisely why transparency matters.

In 2026’s competitive landscape, the question isn’t whether to source executive chairs from China—it’s whether to source blindly or systematically. The tools for systematic verification now exist. The only remaining question is whether buyers will demand them.