Introduction

Transforming beautiful architectural renders into tangible, functional spaces requires one crucial skill: the ability to interpret complex Furniture, Fixtures, and Equipment (FF&E) specifications. Whether you’re an interior designer, project manager, procurement specialist, or facilities coordinator, understanding how to decode FF&E specs is essential for bridging the gap between design vision and physical reality.

What You’ll Learn:

- How to read and interpret technical FF&E specification documents

- Methods for translating render details into procurement requirements

- Techniques for identifying critical specifications versus aesthetic preferences

- Strategies for communicating specs to vendors and contractors

- Quality control processes to ensure spec compliance

- Budget reconciliation between design vision and available products

This comprehensive guide will walk you through the complete process of mastering FF&E specification interpretation, ensuring your projects transition seamlessly from render to reality while maintaining design integrity, staying within budget, and meeting project timelines.

Step 1: Understand the Components of FF&E Specifications

Detailed Instructions

Begin by familiarizing yourself with the standard structure of FF&E specification documents. These typically include:

Furniture Specifications:

- Item descriptions (chairs, tables, desks, storage units)

- Dimensions (width, depth, height)

- Materials and finishes

- Manufacturer and model numbers

- Quantities required

- Color codes and fabric specifications

Fixtures Specifications:

- Built-in elements (millwork, shelving, lighting fixtures)

- Mounting requirements

- Power and data connectivity needs

- Load-bearing specifications

Equipment Specifications:

- Technical equipment (AV systems, appliances, specialized machinery)

- Performance requirements

- Installation prerequisites

- Maintenance requirements

Create a checklist that includes all these components, and use it every time you review a new set of specifications. From render to reality, how to interpret complex FF&E specs begins with understanding this foundational structure.

Tips

- Develop a template: Create a standardized template for organizing specification information that works for your team

- Build a reference library: Keep examples of well-written specs for future reference

- Learn industry terminology: Familiarize yourself with terms like “COM” (Customer’s Own Material), “COL” (Customer’s Own Leather), and “NIC” (Not In Contract)

- Understand CSI format: Many specs follow Construction Specifications Institute formatting standards—learn this system for faster comprehension

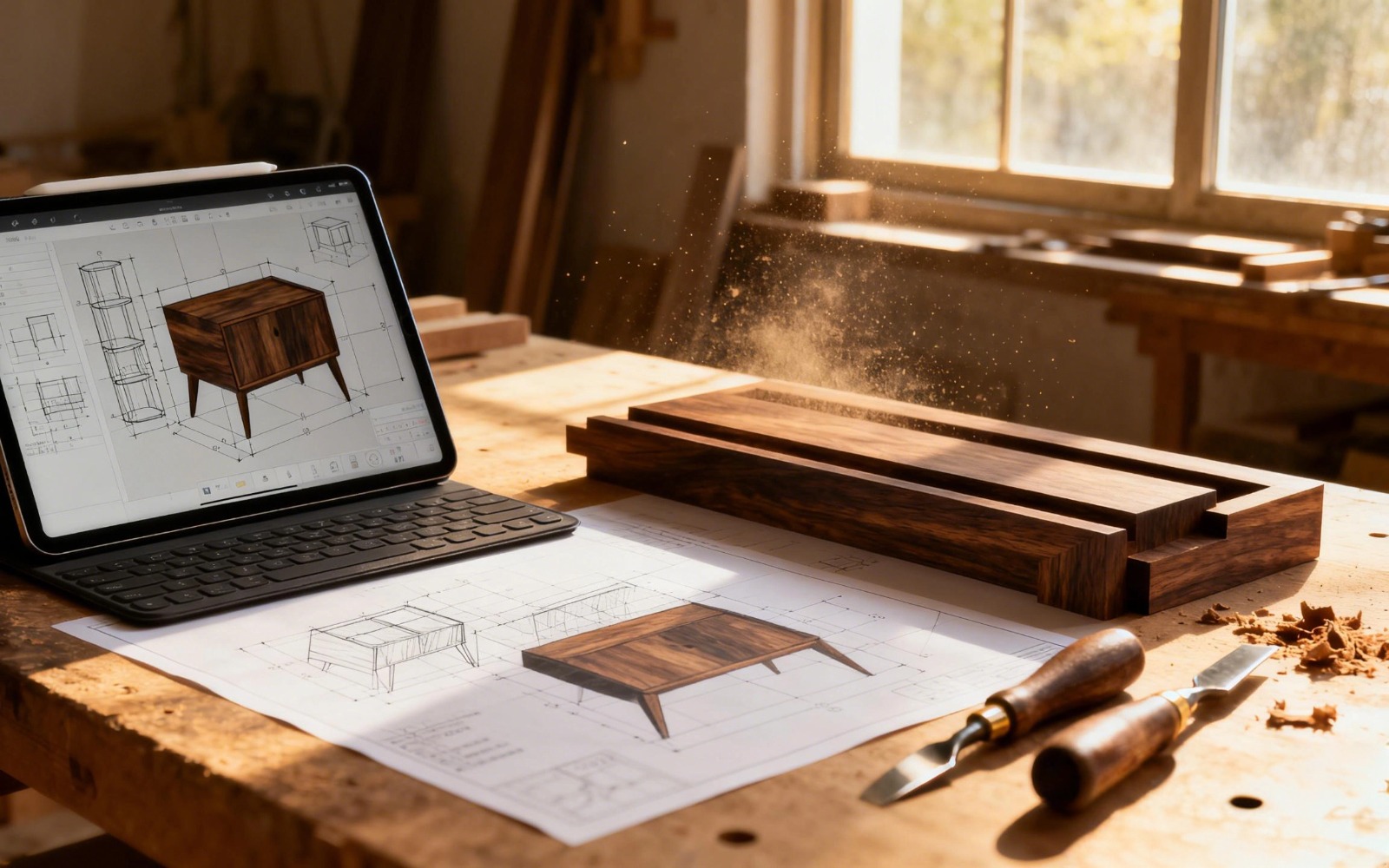

Step 2: Conduct a Detailed Render Analysis

Detailed Instructions

Before diving into specification documents, thoroughly analyze the design renders to extract every possible detail:

Visual Analysis Process:

- Zoom and segment: Examine the render at high resolution, dividing it into zones (reception, workstations, lounge areas, etc.)

- Create a visual inventory: List every visible FF&E item, noting:

- Approximate dimensions relative to human figures in the render

- Color palettes and material appearances

- Spatial relationships and clearances

- Lighting conditions and their effects

- Identify design intent: Determine the aesthetic goals:

- Style direction (modern, traditional, industrial, etc.)

- Brand alignment and corporate identity

- Functional requirements suggested by the layout

- Traffic flow patterns

- Note ambiguities: Mark areas where the render doesn’t provide clear information—these will require clarification from the design team

- Cross-reference with floor plans: Compare renders with accompanying architectural drawings to verify dimensions and spatial relationships

Tips

- Use annotation software: Tools like Bluebeam or Adobe Acrobat allow you to mark up renders digitally with notes and questions

- Create comparison boards: Develop side-by-side visual boards showing render images alongside spec sheets

- Consider lighting effects: Remember that renders often show ideal lighting conditions—actual products may appear different

- Account for scale distortion: Perspective in renders can make items appear larger or smaller than actual dimensions

Step 3: Decode Technical Specifications and Material Callouts

Detailed Instructions

Now translate the technical language in specifications into actionable procurement information:

Material Specification Breakdown:

For Fabrics:

- Fiber content: Understand percentages (e.g., “100% polyester” vs. “65% poly/35% cotton blend”)

- Performance ratings: Decode Wyzenbeek double rubs (durability), colorfastness ratings, and fire ratings (CAL 117, NFPA 260)

- Finish treatments: Identify protective treatments like Crypton, Nano-Tex, or Teflon

- Grade classifications: Understand manufacturer grade systems (Grade A through F typically indicates price points, not quality)

For Wood and Veneers:

- Species identification: Distinguish between walnut, oak, maple, etc.

- Cut types: Understand plain sliced, quarter cut, rift cut veneers

- Finish specifications: Decode stain colors, sheen levels (matte, satin, semi-gloss, gloss)

- Construction methods: Identify solid wood vs. veneer vs. laminate construction

For Metals and Finishes:

- Material types: Steel, aluminum, brass, bronze, etc.

- Finish processes: Powder coat, plating, anodizing, patina

- Color matching systems: RAL, Pantone, or custom manufacturer codes

For Surfaces and Laminates:

- High-pressure laminate (HPL) codes: Wilsonart, Formica, Pionite color and pattern numbers

- Solid surface materials: Corian, Hi-Macs, etc., with color specifications

- Stone and engineered stone: Understand grain patterns, edge profiles, and finish types

Tips

- Request material samples: Always verify specs with physical samples before bulk ordering

- Maintain a material library: Keep samples from previous projects with specification details attached

- Understand equivalents: Know when “or equal” substitutions are acceptable and when exact matches are required

- Check lead times: Some specified materials may have extended lead times that impact project schedules

- Verify current availability: Manufacturers discontinue products—confirm everything is still in production

Step 4: Match Specifications to Available Products

Detailed Instructions

This critical step involves finding actual products that meet the specifications extracted from renders:

Product Sourcing Strategy:

- Start with specified manufacturers: If the spec sheet includes specific manufacturers and model numbers, verify:

- Current product availability

- Lead times for delivery

- Minimum order quantities (MOQs)

- Current pricing vs. budget allowances

- Research approved alternatives: When exact matches aren’t available or exceed budget:

- Identify key performance criteria that must be maintained

- Find products meeting those criteria from alternative manufacturers

- Document differences for design team approval

- Obtain comparable pricing

- Create product comparison matrices: Develop spreadsheets comparing:

- Specifications vs. actual product attributes

- Dimensions (ensure fit within space constraints)

- Materials and finishes

- Performance ratings

- Costs

- Lead times

- Warranty terms

- Address custom requirements: Determine which items require custom fabrication:

- Identify local fabricators or specialized manufacturers

- Obtain detailed fabrication drawings

- Secure quotes and lead time commitments

- Ensure fabricators understand tolerances and quality expectations

- Consider lifecycle costs: Look beyond initial purchase price:

- Maintenance requirements

- Expected lifespan

- Warranty coverage

- Replacement part availability

Tips

- Build vendor relationships: Develop trusted relationships with manufacturer representatives for faster information access

- Use industry resources: Leverage platforms like Architonic, Archiproducts, or manufacturer databases

- Attend trade shows: Industry events provide opportunities to see products firsthand and discover new options

- Request CAD/BIM files: Many manufacturers provide 3D models for space planning verification

- Document everything: Keep detailed records of all product research for future reference and project accountability

Step 5: Verify Dimensional Compliance and Spatial Fit

Detailed Instructions

Ensuring products physically fit within designed spaces is crucial for successful implementation:

Dimensional Verification Process:

- Extract all dimensions from specifications:

- Overall dimensions (W x D x H)

- Clearance requirements

- Door swing radiuses

- Drawer extension depths

- Leg spreads and base dimensions

- Compare against architectural constraints:

- Ceiling heights

- Door and corridor widths for delivery access

- Elevator dimensions and weight capacities

- Room dimensions with wall projections, columns, and mechanical elements

- ADA clearance requirements (where applicable)

- Create spatial mock-ups:

- Use CAD software to place actual product dimensions in floor plans

- Verify circulation paths maintain required clearances

- Check sightlines and ergonomic relationships

- Model delivery paths for oversized items

- Account for tolerances:

- Add buffer space for manufacturing variations (typically ±1/4″ to ±1/2″)

- Consider field conditions and construction tolerances

- Plan for adjustment mechanisms where needed

- Verify technical clearances:

- HVAC vent and return locations

- Electrical outlet positions

- Data and communication port access

- Fire safety equipment clearances

- Emergency egress paths

Tips

- Use 3D visualization: Tools like SketchUp, Revit, or even AR apps help stakeholders visualize actual products in space

- Conduct site verification: Measure actual site conditions rather than relying solely on drawings

- Plan for installation sequences: Ensure large items can be installed before smaller elements block access

- Consider modular solutions: When exact fit is challenging, modular systems offer flexibility

- Document approval: Have stakeholders sign off on spatial plans before procurement

Step 6: Translate Specifications into Procurement Documentation

Detailed Instructions

Transform interpreted specs into clear procurement documents that vendors can execute:

Procurement Package Development:

- Create comprehensive purchase orders that include:

- Complete product descriptions with manufacturer and model numbers

- Precise quantities with room-by-room breakdowns

- Specified materials, finishes, and colors with codes

- Dimensional requirements

- Performance requirements

- Required certifications (fire ratings, environmental standards, etc.)

- Delivery location details

- Required delivery dates with phasing if applicable

- Installation responsibilities (vendor vs. contractor vs. client)

- Develop cut sheets and submittal packages:

- Manufacturer specification sheets

- Finish samples with approval notation

- Installation instructions

- Warranty information

- Maintenance guidelines

- Sustainability certifications (LEED, BIFMA, Greenguard, etc.)

- Establish quality standards:

- Acceptance criteria for delivered goods

- Inspection procedures

- Defect reporting protocols

- Remediation processes

- Include contractual protections:

- Delivery schedule with liquidated damages for delays

- Quality guarantees and warranty terms

- Return and replacement policies

- Payment terms tied to delivery and acceptance milestones

Tips

- Use standardized formats: Consistent procurement documentation reduces errors and speeds processing

- Include visual references: Attach photos from renders or catalog images to prevent misunderstandings

- Specify packaging requirements: Protect finishes with appropriate packaging, especially for multi-phase deliveries

- Address storage: Clarify warehousing responsibilities if delivery timing doesn’t match installation schedule

- Plan for contingencies: Include allowances for minor adjustments or unforeseen conditions

Step 7: Establish Quality Control and Verification Protocols

Detailed Instructions

Implement systematic quality control to ensure delivered products match specifications:

Quality Assurance System:

- Pre-production approval process:

- Request first article samples for custom items

- Conduct factory inspections for large orders

- Review and approve shop drawings

- Confirm finish samples match approved specifications

- Test prototypes for performance requirements

- Receiving inspection procedures:

- Create detailed checklists based on specs

- Inspect immediately upon delivery while carriers present

- Verify quantities against packing lists

- Check for shipping damage

- Confirm model numbers and finish codes

- Measure critical dimensions

- Test functional elements (drawers, adjustments, mechanisms)

- Photograph all items for documentation

- Deficiency documentation:

- Establish clear photo documentation standards

- Create deficiency logs with item details, issue descriptions, and photos

- Set resolution deadlines

- Track remediation progress

- Obtain replacement timelines

- Document all communications with vendors

- Installation verification:

- Monitor installation for proper assembly

- Verify anchoring and stabilization

- Check alignment and levelness

- Test all moving parts

- Confirm safety features function correctly

- Clean and prepare for occupancy

- Final acceptance walkthrough:

- Conduct comprehensive punch list inspection

- Compare installed products against renders

- Verify aesthetic integration

- Test functionality of all elements

- Document completion with photographs

- Obtain warranty documentation

Tips

- Inspect at the warehouse: When possible, inspect products before delivery to site to avoid installation delays

- Maintain inspection records: Detailed documentation protects against disputes and supports warranty claims

- Train your team: Ensure everyone involved understands quality standards and inspection procedures

- Build relationships: Good vendor relationships lead to faster issue resolution

- Plan buffer time: Include time in the schedule for addressing deficiencies before project completion

Step 8: Manage Budget Reconciliation and Value Engineering

Detailed Instructions

Navigate the often challenging process of aligning design specifications with budget realities:

Budget Management Strategy:

- Conduct preliminary budget analysis:

- Price all specified items based on current market rates

- Add freight, taxes, and installation costs

- Include contingencies (typically 5-10% for FF&E)

- Compare total against budget allocation

- Identify budget gaps early

- Prioritize specifications:

- Work with designers to classify specifications:

- Critical: Essential for function or design concept (non-negotiable)

- Important: Significantly impacts design intent (negotiate carefully)

- Flexible: Substitutions acceptable if design intent maintained

- Focus cost-cutting efforts on flexible items

- Work with designers to classify specifications:

- Value engineering approaches:

- Material substitution: Specify laminate instead of solid surface, or similar

- Finish adjustments: Standard finishes instead of custom colors

- Grade changes: Lower fabric grades where appropriate

- Quantity adjustments: Reduce quantities in lower-visibility areas

- Manufacturer alternatives: Comparable products from different sources

- Scope modifications: Eliminate non-essential items

- Maintain design integrity:

- Preserve key design elements that define the space

- Ensure substitutions maintain performance requirements

- Keep overall aesthetic cohesive

- Obtain design team approval for all changes

- Document all changes:

- Create value engineering logs

- Track cost impacts of each change

- Maintain specification history

- Update all documentation to reflect approved changes

Tips

- Negotiate volume pricing: Consolidate orders to achieve better pricing

- Consider phased procurement: Implement essential items first, add others as budget allows

- Explore liquidation and surplus: Quality products at reduced costs from overstocks or project cancellations

- Leverage manufacturer programs: Some offer design trade discounts or project pricing

- Time purchases strategically: Take advantage of manufacturer promotions and sales cycles

Step 9: Coordinate with Project Stakeholders

Detailed Instructions

Effective communication ensures everyone understands and approves the translation from render to reality:

Stakeholder Coordination Process:

- Identify all stakeholders:

- Design team (architects, interior designers)

- Client representatives (facilities managers, executives)

- Project managers and general contractors

- Installation teams

- End users

- Procurement and purchasing departments

- Establish communication protocols:

- Regular update meetings with defined agendas

- Centralized documentation repository (SharePoint, Procore, etc.)

- Clear decision-making hierarchy

- Defined approval processes

- Response time expectations

- Create presentation materials:

- Side-by-side render vs. product comparisons

- Material boards with actual samples

- Dimensional diagrams showing products in space

- Budget summaries with value engineering options

- Timeline charts showing procurement and delivery phases

- Facilitate approval processes:

- Submit organized packages requiring specific decisions

- Provide clear options with pros/cons

- Explain technical considerations in accessible language

- Set deadlines that maintain project schedule

- Document all approvals in writing

- Manage expectations:

- Communicate realistic lead times

- Explain limitations (discontinued products, budget constraints)

- Provide alternatives proactively

- Address concerns transparently

- Keep stakeholders informed of changes and impacts

Tips

- Use visualization tools: Virtual reality or augmented reality can help stakeholders envision final results

- Provide context: Explain how FF&E decisions impact overall project success

- Anticipate questions: Prepare comprehensive information before meetings

- Document decisions: Meeting minutes with action items prevent misunderstandings

- Build consensus: Involve key stakeholders early to avoid late-stage changes

Step 10: Implement Post-Installation Documentation and Closeout

Detailed Instructions

Complete the render-to-reality process with thorough documentation for ongoing facility management:

Closeout Documentation Package:

- Create comprehensive FF&E inventories:

- Room-by-room asset lists

- Manufacturer and model information

- Serial numbers for tracked items

- Purchase dates and costs

- Warranty expiration dates

- Maintenance schedules

- Compile O&M manuals (Operations and Maintenance):

- Assembly instructions

- Care and cleaning guidelines

- Recommended maintenance schedules

- Replacement part information

- Manufacturer contact information

- Troubleshooting guides

- Organize warranty documentation:

- Individual product warranties

- Registration information

- Claim procedures

- Warranty service provider contacts

- Extended warranty options

- Develop touch-up and repair kits:

- Extra fabric samples for future repairs

- Touch-up paints and finishes

- Replacement parts for common wear items

- Cleaning product recommendations

- Supplier information for reordering

- Prepare sustainability documentation:

- Environmental certifications

- Recycling information for end-of-life

- Sustainability metrics for reporting

- Indoor air quality certifications

- Create as-built records:

- Final photographs of installed spaces

- Updated floor plans with actual product placements

- Deviations from original specifications

- Lessons learned documentation

- Vendor performance evaluations

Tips

- Use facility management software: Input data into CAFM or CMMS systems for ongoing management

- Train facility staff: Provide training on care and maintenance of installed FF&E

- Create digital archives: Maintain cloud-based documentation accessible to facility teams

- Establish reorder processes: Make future procurement of replacement items straightforward

- Plan lifecycle management: Schedule periodic reviews to maintain investment value

Conclusion

Mastering the journey from render to reality through complex FF&E specification interpretation is a multifaceted skill that combines technical knowledge, attention to detail, project management, and effective communication. By following this comprehensive ten-step process, you’ll transform aspirational design visions into functional, beautiful spaces that meet both aesthetic and practical requirements.

Key Takeaways:

- Foundation matters: Understanding FF&E specification components and structure is essential before attempting interpretation

- Analysis is critical: Thorough render analysis extracts crucial details that inform procurement decisions

- Technical literacy pays off: Decoding material specifications ensures accurate product sourcing

- Verification prevents problems: Dimensional checks and spatial planning avoid costly mistakes

- Documentation protects all parties: Clear procurement documentation and quality control processes ensure accountability

- Communication bridges gaps: Effective stakeholder coordination aligns expectations with reality

- Budget consciousness: Strategic value engineering maintains design intent while respecting financial constraints

- Closeout sets up success: Comprehensive documentation supports long-term facility management

The ability to interpret complex FF&E specs and successfully implement them distinguishes exceptional professionals in the architecture, design, and construction industries. This skill ensures projects transition smoothly from conceptual renders to tangible spaces that delight clients and serve users effectively for years to come.

As you apply these principles to your projects, you’ll develop increasingly refined judgment about when to strictly adhere to specifications and when flexibility serves the project better. Each project will expand your product knowledge, strengthen your vendor relationships, and enhance your ability to navigate the challenges inherent in bringing designs to life.

Remember that from render to reality, how to interpret complex FF&E specs is not just about technical proficiency—it’s about understanding design intent, respecting budget parameters, maintaining quality standards, and delivering spaces that fulfill their intended purpose while embodying the designer’s vision. Master this process, and you’ll become an invaluable asset to any design and construction team.

Leave a Reply